- 19

- Jan

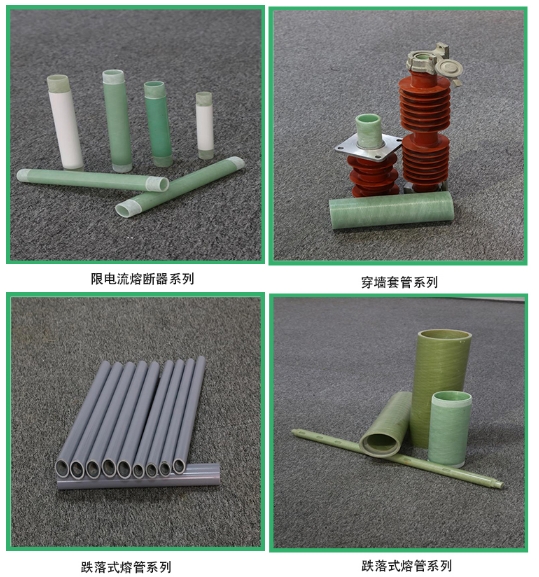

Epoksidik fib fib likidasyon tiyo

Epoksidik fib fib likidasyon tiyo

Epoxy glass fiber winding pipe is made of uninterrupted fiber wet winding, specially developed for structural parts of high-voltage electrical equipment such as reactors, lightning arresters, fuses, transformers, on-load tap-changers, transformers, etc. The product performance parameters meet IEC standards Require.

paramèt debaz:

1: ang likidasyon, 45 ~ 65 (ang lan likidasyon ka ajiste selon kondisyon diferan pou reyalize pi bon kondisyon pèfòmans mekanik);

2: kontni fib (rapò pwa), 70 ~ 75%;

3: Dansite, 2.00 g / cm3;

4: To absòpsyon dlo, mwens pase 0.03%;

5: Axial koyefisyan ekspansyon tèmik, 1.8 E-05 1/K;

6: Tanperati tranzisyon an vè, 110 ~ 120 ℃;

7: Rezistans chimik. Lwil mineral: ekselan;

8: Solvang ak asid dilye: ekselan;

9: Tensile modil elastisite, axial 14000 MPa;

10: Fòs rupture; axial 280 MPa; sikonferans 600 MPa;

11: Chea fòs: 150 MPa;

12: Fòs flexural: 350 MPa nan direksyon axial;

13: fòs konpresyon: axial 240 MPa;

14: Pèmitivite relatif 2-3.2;

15: Faktè pèt Dielectric 0.003-0.015;

16: Kapasite egzeyat pasyèl ≤5;

17: Fòs izolasyon: axial 3~6 kV; radial 10~12 kV;

18: Enpak Zeklè: 110 KV

19: Chòk frekans pouvwa: 50 KV;

20: Chalè rezistans klas: B, F, H klas

21: Dyamèt enteryè> 5mm; dyamèt ekstèn <300mm; longè <2000mm.

The above data is for reference only, the casing parameters we produce are customized for each customer’s needs

Our products have been exported to the United States, Germany, South Korea, Japan, Europe, Russia and other countries.