- 19

- Jan

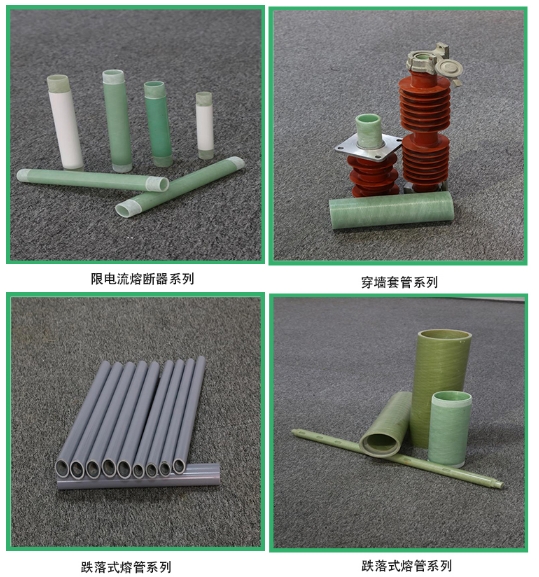

Epoxy khalase faeba matsoelintsoeke phala

Epoxy khalase faeba matsoelintsoeke phala

Epoxy glass fiber winding pipe is made of uninterrupted fiber wet winding, specially developed for structural parts of high-voltage electrical equipment such as reactors, lightning arresters, fuses, transformers, on-load tap-changers, transformers, etc. The product performance parameters meet IEC standards Require.

Litekanyetso tsa mantlha:

1: Winding angle, 45~65 (leqhubu la matsoelintsoeke le ka fetoloa ho latela litlhoko tse fapaneng ho fihlela litlhoko tse ntle tsa ts’ebetso ea mochini);

2: Likahare tsa fiber (karolelano ea boima), 70~75%;

3: Boima, 2.00 g/cm3;

4: Sekhahla sa ho monya metsi, ka tlase ho 0.03%;

5: Coefficient ea katoloso ea mocheso oa Axial, 1.8 E-05 1/K;

6: Khalase phetoho mocheso, 110~120 ℃;

7: Ho hanyetsa lik’hemik’hale. Oli ea diminerale: e ntle haholo;

8: Hlakola le ho hlapolla acid: e ntle haholo;

9: Tensile modulus ea elasticity, axial 14000 MPa;

10: Matla a thata; axial 280 MPa; circumferential 600 MPa;

11: Matla a ho kuta: 150 MPa;

12: Matla a Flexural: 350 MPa ka tataiso ea axial;

13: Matla a hatellang: axial 240 MPa;

14: Tumello e amanang le eona 2-3.2;

15: Dielectric loss factor 0.003-0.015;

16: Matla a ho ntša karolo e itseng ≤5;

17: Matla a insulation: axial 3~6 kV; mahlaseli 10~12 kV;

18: Tšusumetso ea lehalima: 110 KV

19: Tšabo ea maqhubu a matla: 50 KV;

20: Kereiti ea ho hanyetsa mocheso: B, F, H kereiti

21: bophara ba ka hare> 5mm; bophara ba ka ntle <300mm; bolelele <2000mm.

The above data is for reference only, the casing parameters we produce are customized for each customer’s needs

Our products have been exported to the United States, Germany, South Korea, Japan, Europe, Russia and other countries.