- 10

- Aug

Na mgbakwunye na ike ike elu, kedu ngwa ndị ọzọ ka ọkụ ọkụ induction nwere?

Na mgbakwunye na ike ike elu, kedu ngwa ndị ọzọ ka ọkụ ọkụ induction nwere?

Na mgbakwunye na ike ike elu, induction ọkụ ọkụ a na-ejikwa n’akụkụ ndị a:

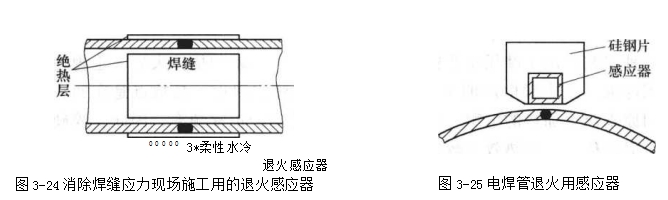

(1) Nchekwa nchekasị na nhazi nhazi nke foto 3-24 na-egosi eriri mmiri na-agbanwe agbanwe nke na-ekpuchi eriri eriri nke casing, ma na-eme ka mgbakasị ahụ kwụsị ma ọ bụ na-agbanye n’ọnọdụ ịgbado ọkụ. Onyonyo 3-25 na-egosi inductor linear nke nwere mpempe akwụkwọ nchara silicon maka imechi eriri ogologo na-aga n’ihu nke ọkpọkọ butt-welded. Inductor linear na-eme ka weld dị elu karịa okpomọkụ, nke mere na a na-emegharị usoro ahụ. Ngwunye abụọ nke traktọ tubing dị elu na-agba ọkụ (nchara 20), a na-ejikwa induction normalizing na-eweghachi ọka dị n’isi shọvelụ ahụ ka ọ dị mma.

(2) Ọkụ maka penetration quenching na tempering mmanụ ọma engineering, mpụta dayameta dị n’etiti Φ60 ~ 410, mgbidi ọkpụrụkpụ bụ n’etiti 5 ~ 16mm, na 1000Hz etiti ugboro ike ọkọnọ e ji penetration kpo oku quenching na tempering (600 ~ 700 ℃) Ọ na-rụrụ na ihe etiti ugboro ike ọkọnọ. A na-ejikwa ike siri ike na iwe ọkụ nke oghere ịsa ahụ nke ọma n’ọkụ diathermy.

(3) A na-eji ọkụ induction na-adọta tube. A na-ebelata dayameta nke tube a na-adọta oyi na ọnọdụ oyi, na mbelata dị ntakịrị oge ọ bụla, na mgbakwunye na nkwụsịtụ na pickling, usoro ahụ dị mgbagwoju anya. Ojiji nke ikpo ọkụ induction na-adọta tube nwere ike ịbawanye nbelata dayameta site na ugboro 1.5, ma wepụ ihe nkwụsịtụ, pickling na usoro ndị ọzọ.