- 10

- Aug

Ntle le ho thatafatsa holim’a metsi, ke lisebelisoa life tse ling tse nang le lisebelisoa tsa ho futhumatsa ka induction?

Ntle le ho thatafatsa holim’a metsi, ke lisebelisoa life tse ling tse nang le lisebelisoa tsa ho futhumatsa ka induction?

Ntle le ho thatafatsa bokaholimo, sebopi sa ho futhumatsa li boetse li sebelisoa likarolong tse latelang:

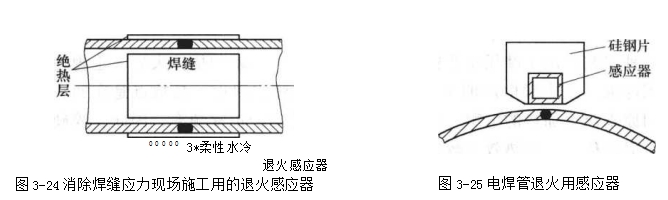

(1) Ho imolla khatello ea maikutlo le ho tloaeleha Setšoantšo sa 3-24 se bonts’a coil e pholileng e pholileng ka metsi e phuthelang lesela la butt ea casing, ‘me e etsa ho imolla khatello ea kelello kapa ho koala sebakeng sa welding. Setšoantšo sa 3-25 se bonts’a inductor ea mela e nang le lishiti tsa tšepe tsa silicon bakeng sa ho koala litšepe tse tsoelang pele tsa lipeipi tse cheselitsoeng butt. The linear inductor futhumatsa tjheseletsa ka holimo mocheso, e le hore sebopeho e recrystallized. Lintlheng ka bobeli tsa li-tubing tse nang le khatello e phahameng ea terekere li tuka (litšepe tse 20), ‘me ho tloaeleha ha induction ho boetse ho sebelisoa ho khutlisetsa lijo-thollo tse hloohong ea kharafu hore li tloaelehe.

(2) Liphaephe tsa ho tima le ho futhumatsa oli ea seliba sa boenjiniere, bophara ba kantle bo pakeng tsa Φ60~Φ410, botenya ba lerako bo pakeng tsa 5 ~ 16mm, ‘me phepelo ea motlakase ea 1000Hz ea mahareng e sebelisitsoe bakeng sa ho tima le ho futhumatsa ho kenella ha mocheso (600 ~ 700 ℃) E boetse e etsoa ka phepelo ea motlakase ea maqhubu a mahareng. Ho thatafatsa le ho belisoa ha likheo tsa screw ho boetse ho sebelisitsoe ka katleho liboping tsa diathermy.

(3) Ho futhumatsa ho sebelisoa ho hula tube. Bophara ba tube e huloang ke serame e fokotsehile sebakeng se batang, ‘me phokotso e nyane nako le nako, ho phaella ho annealing le pickling, mokhoa ona o rarahane. Ts’ebeliso ea ho futhumatsa ka induction ho hula tube e ka eketsa phokotso ea bophara ka makhetlo a 1.5, ‘me ea felisa ho ts’oaroa, ho khetha le lits’ebetso tse ling.