- 02

- Dec

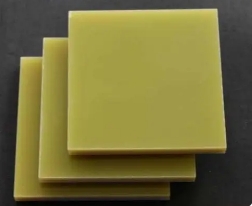

The important role of additives for epoxy glass fiber cloth laminate

The important role of additives for эпоксиддүү айнек була кездемеден жасалган ламинат

In the production of epoxy glass fiber cloth laminate, high-density polyethylene board can be added, and in the process of relative low density, it can increase the stable melting temperature and the relative temperature of the melting point. With an ultra-high molecular weight of 7 million, it has high impact resistance, high impact kinetic energy absorption rate and strong modulus under high stress, outstanding abrasion resistance and sliding properties, and dimensional stability even when heated sex. Anti-ultra-low temperature -265℃. Even at low temperatures and even at low temperatures, it still maintains very excellent tensile strength and notch impact strength, acid and pigment resistance.

Epoxy glass fiber cloth laminate has excellent mechanical properties, excellent rigidity, as hard as steel, outstanding performance in toughness, and good elasticity. Of course, it can withstand very strong impact. There is another point, that is, the creep resistance, which is very prominent in the stability of the material. Coupled with various forms, convenient curing, strong adhesion, and low shrinkage, epoxy glass fiber cloth laminates have a broad market for high-insulation structural parts for machinery, electrical appliances and electronics.

Of course, these are all essential to additives. Its main component is epoxy resin, which is an insulating board laminated after glass cloth and epoxy resin are combined. In determining performance, the role of additives such as curing agents, modifiers, fillers, and diluents is extremely important. Because they are used as an additive of epoxy resin*, which determines whether the product can be molded and cured. If it cannot be molded and cured, there is no epoxy glass fiber cloth laminate. Through the performance adjustment effect of additives, the epoxy glass fiber cloth laminate can be applied in more fields. By changing the ratio of additives, the diversification of forms can be realized from lower viscosity to high melting point solids, and the solidification at any temperature within the temperature range of 0-180°C can be almost realized.

The use of additives promotes the environmentally friendly reaction of the epoxy resin, no water or any volatile side-effect products are released, and the shrinkage is low, so that the internal stress generated is relatively reduced, which helps to The adhesion strength is greatly improved. Of course, additives also have certain side effects. The epoxy resin itself is non-toxic, but as the demand changes, the type and composition of additives are different, and the performance of the epoxy resin will undergo certain changes, resulting in toxicity. Therefore, attention must be paid. This is the reason why LCP, which has excellent wear resistance and anti-wear properties, is used as an integrated circuit packaging material by adding high fillers to a certain extent instead of epoxy glass fiber cloth laminate as a coil bobbin packaging material.