- 14

- Dec

What are the characteristics of ball screw induction heating furnace quenching?

өзгөчөлүктөрү кандай ball screw induction heating furnace quenching?

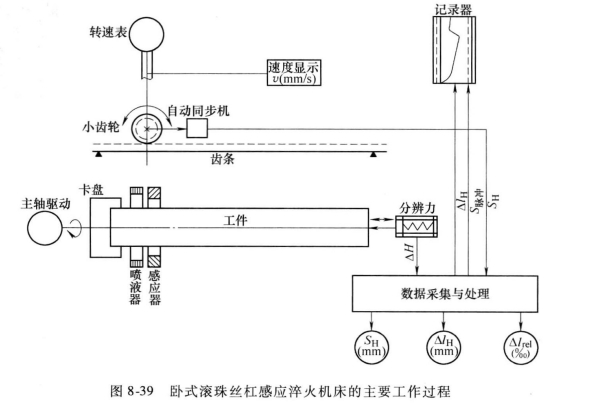

The quenching of ball screw induction heating furnace is generally horizontal, because the screw is 5~6m long, if the vertical type is used, even if the transformer and the inductor are used to move, its operation is still very inconvenient. Figure 8-39 shows the main working process of quenching in a horizontal ball screw induction heating furnace. This ball screw induction heating furnace uses a thyristor intermediate frequency power supply for quenching, and has two power and frequency levels, namely 160kW/10kHz and 50kW/30kHz. The former is used for screws with thicker diameters, and the latter is used for screws with thinner diameters. The maximum workpiece length is 6m.

The key technology of ball screw induction hardening is to control its deformation. Deformation has two aspects: the first is bending deformation, which is a problem that slender workpieces must encounter; the second is elongation deformation, which is the elongation and shortening of its pitch for a ball screw. If the pitch elongation is too much after quenching, as the length of the screw increases, the cumulative elongation exceeds a certain value, and the pitch size exceeds the tolerance, the screw will be scrapped.

Some measures have been taken in the design of this machine tool: ①Using a half-ring inductor, its current in addition to the circumferential current, there is also a longitudinal part, so that both the top and bottom of the thread can be heated; ②The lead screw is straddled by the spacer Scanning and quenching is carried out on the upper part. Because the positioning block is tightly straddling the lead screw, the equal gap is maintained, and the lead screw is rotated and heated, which can make the heating uniform; ③The limited deformation roller supporting the lead screw is installed to reduce the bending deformation.

The feature of this machine is the length correction. The tempering of the ball screw is also carried out on this machine, using the return stroke for tempering. After tempering, it is cooled again on the machine tool to complete the heat treatment process. The computer of this machine tool is connected to the printer to print out the measurement results of each quenched part. This report can be used as a quality record card. The power supply for quenching of ball screw induction heating furnace has now been developed into three frequencies, and there are more appropriate choices for screws of different diameters.