- 08

- Apr

How does crankshaft induction heating furnace quenching work?

How does crankshaft induction heating furnace quenching work?

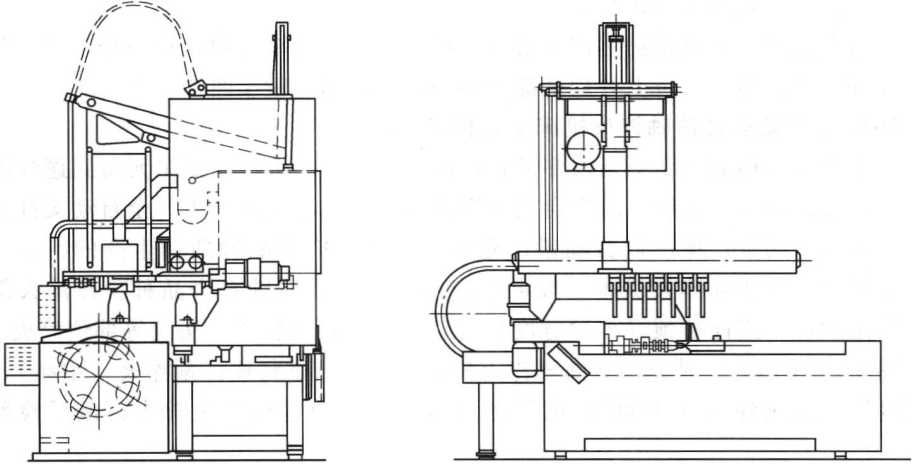

The quenching of the semi-automatic crankshaft induction heating furnace with automatic sensor replacement is shown in Figure 8-17. Improved on the basis of the semi-automatic crankshaft hardening machine, mainly to solve the fatigue problem of the operator when replacing the inductor. A set of seven inductors are stored in a storage box. When the operator installs the four crankshafts on the center of the star bracket, the machine tool automatically performs journal heating, star bracket indexing, and crankshaft immersion quenching in sequence. After a group of journals are quenched, the drive motor of the quenching trolley sequentially stops the trolley to the specified position and automatically changes the sensor. Its action is similar to that of a CNC giant bed and an iron bed. This kind of induction heating furnace quenching can solve the fatigue problem of the operator. The productivity of the machine tool is generally 7-15 crankshafts per hour, which mainly depends on the number of crankshaft journals, and is usually calculated by quenching one journal in 30s.

Figure 8-17 Quenching of a semi-automatic crankshaft induction heating furnace with automatic sensor replacement