- 07

- Dec

Working mode of copper tube induction heating continuous annealing production line

Working mode of copper tube induction heating continuous annealing production line

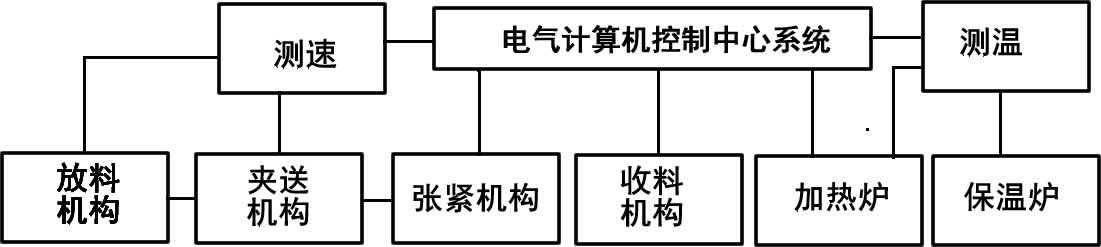

The copper tube induction heating continuous annealing production line is fully automatic. After completing the tube guiding work, the operator only needs to set the annealing line speed and annealing temperature online, and all other operations are automatically realized by the computer. The control system structure of TL400 is shown in the figure.

The control system has the following characteristics:

(1) The drive system of the rewinding and unwinding mechanism and the clamping and correcting mechanism adopts a series of vector controllers, and the drive system of the tensioning mechanism adopts a DC controller.

(2) The computer system adopts Taiwan Advantech. The operating system xp can realize networked control.

(3) The human-machine interface adopts Samsung’s 23-inch LED screen touch screen, which is very convenient for operation and debugging personnel to monitor the system.

(5) Application software In addition to the conventional logic control, the pipe induction continuous annealing controller application software has the following functions:

① P-V (power-speed) automatic follow function. According to pipe specifications and annealing process requirements, intermediate frequency power supply

The output power automatically follows the speed of the copper tube to ensure the stability of the annealing temperature. The speed of TL400 copper pipe can be continuously adjusted from 20 to 400m/min.

②Use the measured module to calculate the control voltage of the intermediate frequency power supply. The method is simple and reliable, and is not subject to temperature measurement devices,

The influence of the working status of the power measurement system. The precise power control model ensures the control accuracy of the annealing furnace.

③Micro-tension control function of copper tube. The copper tube is automatically built up during the heating process, so that the copper tube is annealed

It is not stretched or collapsed in the state.

④ Rewinding and unwinding speed compensation function. Use looper detection and rewinding and unwinding speed compensation calculation to ensure the rewinding and unwinding of the material basket.

The discharge speed changes with the linear speed of the annealed copper tube, and the discharge is stable and the collection is balanced.

https://songdaokeji.cn/13909.html

https://songdaokeji.cn/13890.html