- 24

- Sep

Steel pipe spray heating furnace

Steel pipe spray heating furnace

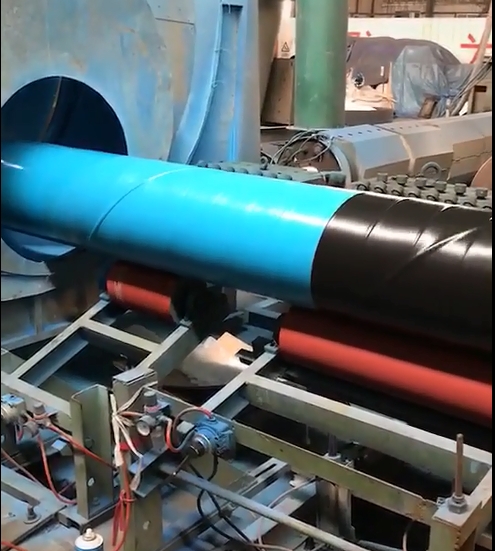

The steel pipe spray heating furnace is an induction heating furnace specially designed and manufactured for heating the pipeline before the pipeline anticorrosion spraying. Pipeline anti-corrosion spraying is also a popular pipeline anti-corrosion measure in the past ten years. This kind of spraying needs to heat the pipeline to a certain temperature. At this temperature, the sprayed anti-corrosion agent will be closely combined with the pipeline to achieve the pipeline anti-corrosion effect. The pipeline after spraying The corrosion-resistant service life can reach more than 30 years, which has significant economic and social economic benefits. The steel pipe spray heating furnace heats the pipeline by induction heating, which is the most efficient and effective heating method among all pipeline heating methods.

The steel pipe spraying heating furnace production line is composed of sandblasting processing unit, transportation roller table, painting service platform, induction heating furnace, internal and external painting unit, water curtain, infrared thermometer system software, etc.

The pipes to be sprayed on the steel pipe spraying heating furnace production line are first subjected to sandblasting and anti-rust treatment, and the pipe workpieces that meet the standards are sent to the spraying preparation roller table through the transportation roller table, and the pipe turning machine sends it to the anti-corrosion spraying table stably , At this time, the inner spray gun is sleeved into the pipe. All the equipment is ready to spray gradually. The pipeline rotates forward at the rate specified by the process. It is first heated in the induction heating furnace. After heating to the processing temperature, the top of the pipe head reaches the outer spraying unit (when the inner and outer spraying guns of the inner and outer spraying units are turned on separately, the inner and outer paint spraying guns of the inner and outer Paint outside. After spraying and roller conveyor, the painted pipeline enters the high pressure water curtain for cooling. If there is no problem in the detection, it is included in the packaging procedure. The entire production line of the steel pipe spraying heating furnace is controlled by the computer in the main control room.