- 26

- Jul

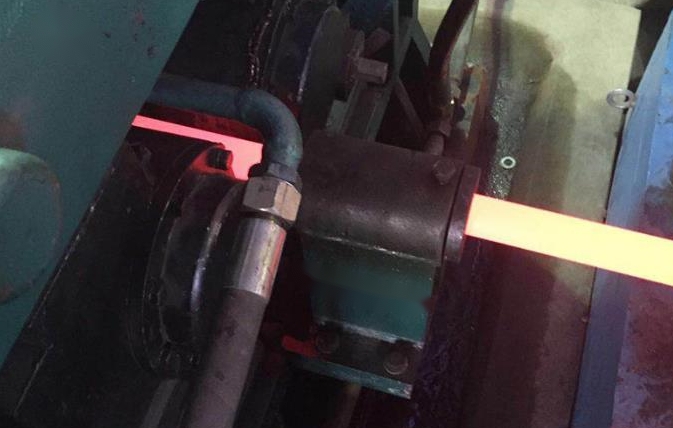

Hot-rolled seamless steel pipe equipment

- 27

- júla

- 26

- júla

Hot-rolled seamless steel pipe equipment

Hot-rolled seamless steel pipe equipment has the characteristics of fast production speed, high production efficiency, low production cost, reliability and durability.

Hot-rolled seamless steel pipe equipment parameters:

1. Heating seamless steel pipe material: carbon steel, alloy steel

2. Diameter range of seamless steel pipe: diameter 10mm~406mm, length range: more than 2m

3. Intermediate frequency power supply for seamless steel pipe heating: KGPS160KW-8000kW

4. Power consumption of hot-rolled seamless steel pipe equipment: Calculated according to the customer’s workpiece material and diameter, heating temperature, running speed, etc.

5. PLC control of hot-rolled seamless steel pipe equipment: specially customized man-machine interface, highly user-friendly operation instructions, remote operation console of industrial computer system with touch screen, all-digital and high-depth adjustable parameters, so that you can control the equipment more Handy. There is a Haishan electric furnace “one-key restoration” system and a multi-language switching function.

6. Infrared temperature measurement PLC temperature closed-loop automatic temperature control system.

7. Material storage system: The thick-walled square tube is welded to form a material storage platform, with a slope of 13 degrees, and can store more than 20 pieces of material.

PLC control of hot-rolled seamless steel pipe equipment:

The hot-rolled seamless steel pipe equipment is controlled by PLC. The input and output voltage of the PLC adopts DC24V power supply, and each sensor and solenoid valve adopts DC24V power supply. The PLC has a fault diagnosis program, which can diagnose the faults that occur when the equipment is running, and Send the fault information to the fault alarm light for display. All-digital, high-depth adjustable parameters, simple and easy to operate. The signals of circuit breakers, AC contactors, thermal relays of all motors and the operating status detection signals of mechanical devices driven by the motors all enter the PLC system.