- 05

- Sep

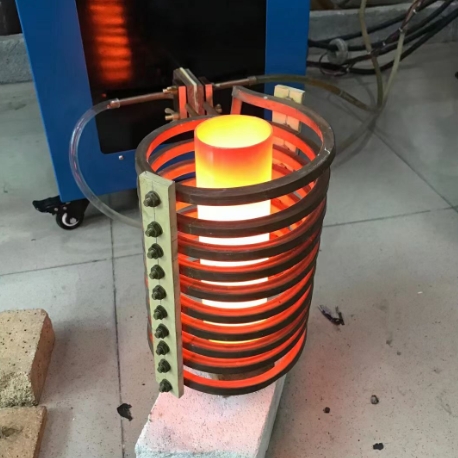

Chengetedzo yekutenga yakakwira frequency yekudzima maturusi emuchina

Kungwarira pakutenga high frequency quenching muchina maturusi

1. Chekutanga pane zvese, zvinodikanwa kuti unzwisise ukuru hwechishandiso chinodzimwa, uye sarudza yakakodzera michina yemhando. Kudzima, hazvikurudzirwe kushandisa muchina une simba shoma rekudzima, izvo zvinokanganisa kudzima kwese.

2. Kudzika uye nzvimbo yekudziya inodiwa pakudzima kwepamusoro-frequency; kudziyisa kudzika, kureba kwekudziya kana nzvimbo yekudziya, ingave kupisa kwese kunodiwa, iyo yakaoma layer inoda yakadzika layer ine yakaderera oscillation frequency, uye isina kudzika kuomarara layer inosarudzwa.

3. Iyo yekupisa yekumhanyisa inodiwa pakudzima kwepamusoro-frequency; iyo inodiwa yekudziya yekumhanyisa inokurumidza, uye simba rinofanira kunge rakakura, uye mhedzisiro yekudzima ichava nani kana kukurumidza kwekudzima kuri kukurumidza.

4. Kuenderera mberi kwekushanda nguva ye-high-frequency quenching midziyo; inoramba ichishanda nguva yakareba, uye induction yekudziya michina ine simba rakati kurei inosarudzwa.

5. Iyo yekubatanidza kureba ye-high-frequency induction equipment; iyo yekubatanidza yakareba, uye inotoda kubatanidzwa netambo yakanyoroveswa nemvura, uye iyo induction inodziya midziyo ine simba rakakwirira inofanira kusarudzwa zvishoma.

6. High-frequency production process; kazhinji kutaura, yekudzima, welding uye mamwe maitiro, simba rinogona kusarudzwa ridiki, uye frequency inogona kusarudzwa yakakwirira; annealing, tempering uye mamwe maitiro, simba rehukama rinenge rakakura, uye frequency inosarudzwa yakaderera; red punching, Kune inopisa calcining, smelting, nezvimwewo, kana nzira ine yakanaka diathermy effect ichidiwa, simba rinofanira kusarudzwa kumusoro uye frequency yakaderera.

- Izvo zvinhu zvemushini wekudzima chishandiso workpiece; iyo simbi ine yakakwira yekunyungudika ine simba rakawanda, uye iyo yakaderera yekunyungudika ine simba rakaderera; iyo resistivity idiki, simba rakakwirira, uye resistivity yakakwirira, simba idiki.