- 05

- Sep

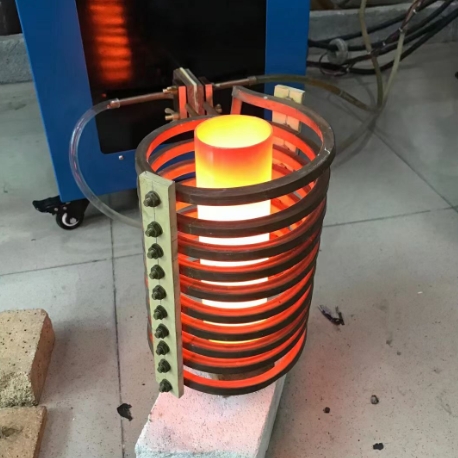

Precautions for purchasing high frequency quenching machine tools

Precautions for purchasing yuqori chastotali söndürme dastgohlari

1. Avvalo, söndürülecek ish qismining o’lchamini tushunish va tegishli uskuna modelini tanlash kerak. Söndürme uchun, söndürme uchun kam quvvatli mashinadan foydalanish tavsiya etilmaydi, bu umumiy söndürme ta’siriga ta’sir qiladi.

2. The depth and area of heating required for high-frequency quenching; heating depth, heating length or heating area, whether the overall heating is required, the hardness layer requires a deep layer with a low oscillation frequency, and a shallow hardness layer is selected.

3. Yuqori chastotali söndürme uchun zarur bo’lgan isitish tezligi; talab qilinadigan isitish tezligi tez va quvvat nisbatan katta bo’lishi kerak va söndürme tezligi tez bo’lsa, söndürme effekti yaxshi bo’ladi.

4. Continuous working time of high-frequency quenching equipment; continuous working time is long, and induction heating equipment with slightly larger power is relatively selected.

5. The connection distance of the high-frequency induction equipment; the connection is long, and even needs to be connected by a water-cooled cable, and the induction heating equipment with higher power should be selected relatively.

6. High-frequency production process; generally speaking, for quenching, welding and other processes, the power can be selected relatively small, and the frequency can be selected higher; annealing, tempering and other processes, the relative power is relatively large, and the frequency is selected lower; red punching, For hot calcining, smelting, etc., if a process with good diathermy effect is required, the power should be selected higher and the frequency lower.

- The material of the quenching machine tool workpiece; the metal material with high melting point is relatively high power, and the low melting point is relatively low power; the resistivity is small, the power is high, and the resistivity is high, the power is small.