- 15

- Sep

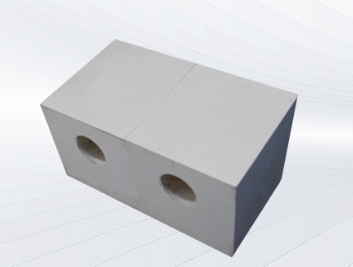

Isitena esidityanisiweyo

Isitena esidityanisiweyo

Izibonelelo zeMveliso: ubushushu obuqhelekileyo obuphezulu bokuqina (ukuya kuthi ga kwi-340MPa), ubushushu obuphezulu bokuthambisa ubushushu (ubushushu bokuqala bokuthamba bungaphezulu kwe-1700 ° C), uzinzo lweekhemikhali olulungileyo, i-asidi elungileyo kunye ne-alkali slag, intsimbi etyhidiweyo kunye neglasi yokumelana.

Isicelo seMveliso: Ezona zinto zisetyenziswayo kwizitena ze-und-β corundum izitena ezisetyenziswa kakhulu Icandelo lokucacisa, icandelo lokupholisa, iphuli yokusebenza, njl njl. Ukongeza, izitena ezihlanganisiweyo ze-α-β corundum ziyasetyenziswa nakwisilingi nakwisakhiwo esingaphezulu seefestile zeglasi. Izitena ze-beta corundum ezisetyenzisiweyo zinokusetyenziselwa kuphela ukwakheka okuphezulu kwesitovu seglasi ngothuli lwe-SO2, njengakwisakhiwo esiphezulu sedama elisebenzayo, udonga lwebele kufutshane nesitshisi, isitshisi somlilo omncinci, udonga oluxhonywe njalo njalo .

Ingcaciso yeMveliso

Isigaba esiphambili sekristal yesitena esidityanisiweyo se-corundum yi-corundum, kwaye umxholo we-Al2O3 ngokubanzi uphezulu kune-93%. Ukuxhathisa kukothuka kwe-thermal kwezitena ezihlanganisiweyo ze-corundum kunxulumene kakhulu nomzimba. Ukuxinana kweemveliso zecorundum kunokumelana ngcono nokubola, kodwa ukuxhathisa okungathathi ntweni kwe-thermal. Izitena ze-corundum ezidityanisiweyo zingahlulwa-hlulwa zibe zizitena ezihlanganisiweyo, izitena ezi-α-β zekorundum kunye nezitena ezihlanganisiweyo.

Iimpawu zezitena ezihlanganisiweyo ze-corundum:

1.Ukucinezelwa okuphezulu kwamandla kubushushu begumbi (ukuya kuthi ga kwi-340MPa)

Ubushushu obuthambisa umthwalo ophezulu (ubushushu bokuqala bokuthamba bungaphezulu kwe-2 ℃)

3. Uzinzo lweekhemikhali olulungileyo

4. Ukumelana kakuhle ne-asidi kunye ne-alkali slag, isinyithi esinyibilikisiweyo kunye neglasi

| iprojekthi | α-ICorundum Brick | a-β iBrick Brund | ick Isitena seCorundum |

| SiO2% | |||

| Al2O3% | > 99 | > 94 | > 94 |

| Fe2O3% | |||

| Na2O% | <7 | ||

| MgO% | |||

| TiO2% | |||

| I-porosity ebonakalayo | 0 ~ 20 | 0 ~ 5 | 5 ~ 15 |

| Ubuninzi bobunzima g / cm3 | > 3.8 | > 3.4 | > 3.0 |

| Flexural amandla MPA | > 70 | > 150 | > 20 |

| Ukutsala kwakhona | > 1900 |