- 15

- Sep

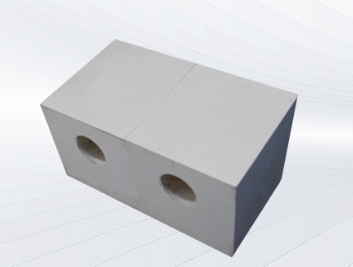

Fused corundum brick

Fused corundum brick

Product advantages: high normal temperature compressive strength (up to 340MPa), high load softening temperature (initial softening temperature higher than 1700°C), good chemical stability, good acid and alkali slag, molten metal and glass resistance.

Product application: The main uses of fused α corundum bricks are borosilicate glass kilns, high-temperature tunnel kiln sintering belts, graphite roasting furnace working linings, non-ferrous metal smelting furnaces, etc. Fused α-β corundum bricks are widely used in the clarification section, cooling section, working pool, etc. of glass kilns. In addition, fused α-β corundum bricks are also used in the ceiling and upper structure of glass furnaces, continuous casting distributor runners and heating furnace slide rails. Fused beta corundum bricks can only be used for the upper structure of the glass kiln with SO2 dust, such as the upper structure of the working pool, the breast wall near the burner, the burner of the small furnace, the hanging wall and so on.

product description

The main crystal phase of fused corundum brick is corundum, and the content of Al2O3 is generally higher than 93%. The thermal shock resistance of fused corundum bricks is closely related to the body. Dense corundum products have better corrosion resistance, but poor thermal shock resistance. Fused corundum bricks can be further divided into fused α corundum bricks, fused α-β corundum bricks and fused β corundum bricks.

Characteristics of fused corundum bricks:

1. High compressive strength at room temperature (up to 340MPa)

2. High load softening temperature (initial softening temperature is higher than 1700℃)

3. Good chemical stability

4. Good resistance to acid and alkali slag, molten metal and glass

| project | α-Corundum Brick | a-β Corundum Brick | β Corundum Brick |

| SiO2 % | <0.5 | <1.5 | <0.5 |

| Al2O3 % | >99 | >94 | >94 |

| Fe2O3 % | <0.1 | <0.1 | <0.1 |

| Na2O % | <0.8 | <4.5 | <7 |

| MgO % | <0.1 | <0.1 | <0.1 |

| TiO2 % | <0.1 | <0.1 | <0.1 |

| Apparent porosity % | 0~20 | 0~5 | 5~15 |

| Bulk density g/cm3 | >3.8 | >3.4 | >3.0 |

| Flexural strength Mpa | >70 | >150 | >20 |

| Refractoriness ℃ | >1900 |