- 25

- Nov

Kungasetshenziswa isikhathi esingakanani ulayini lwangaphakathi lwesithando somlilo esincibilikayo?

Kungasetshenziswa isikhathi esingakanani ulayini lwangaphakathi lwesithando somlilo esincibilikayo?

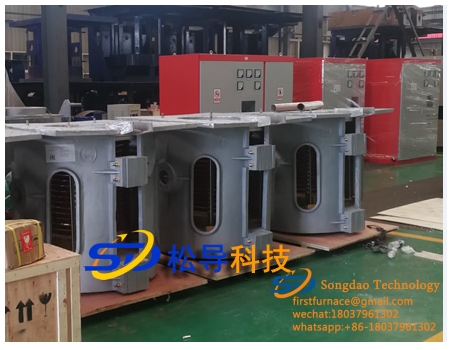

1. Izinto zokwakha zendwangu yodonga lwesithando somlilo we-induction melting yisihlabathi se-quartz kanye nezinto eziphezulu ze-alumina. Impahla ye-alumina ephezulu ifaneleka kakhulu kwizithando zokuncibilika zokungeniswa ngaphansi kuka-500kg, futhi ulayini lwesithando somlilo weziko lokuncibilika lokungeniswa ngaphezu kuka-500kg lwenziwe ngesihlabathi se-quartz esomile.

2. Isihlabathi se-quartz sifaneleka kakhulu ekuncibilikiseni isithando somlilo. Izinto zesihlabathi se-quartz zenziwe ngamaminerali emvelo, futhi ikhwalithi yayo incike ikakhulukazi kokuqukethwe kwe-SiO2 kanye nefomula yayo yosayizi wezinhlayiyana. Ukushintsha ukukhiqizwa kodonga lwesithando somlilo kungandisa impilo yesithando somlilo. I-acid furnace wall lining iwudonga lwesithando somlilo olwakhiwe nge-asidi oxide. I-oxide esetshenziselwa ukwenza uhlaka lwesithando somlilo esine-asidi ikakhulukazi i-SiO2. Cishe zonke izindonga zodonga lwesithando somlilo we-asidi zenziwe ngezinto eziphikisayo ezisekelwe ku-SiO2, ezifanele ngokukhethekile izithando zokushisa ezinkulu ezinomthamo we-5-30T. Ngokusebenzisa izivivinyo, uhlobo lokuqala lwezinkomba zomzimba nezamakhemikhali zesihlabathi se-quartz zine-coefficient yokunweba engu-7% -9%, kanti uhlobo lwesibili lune-coefficient yokwandisa engu-0.5% -2%. Uhlobo lwesibili kanye nosayizi wezinhlayiyana zifaneleka kakhulu ukusetshenziswa kodonga lwesithando somlilo wesithando somlilo esincibilikayo. .