- 28

- Dec

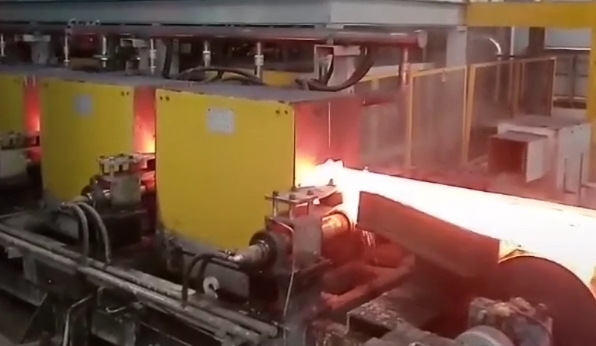

I-billet online induction yokushisa isithando somlilo

I-billet online induction yokushisa isithando somlilo

A. Izimo ezikhona zomsebenzisi kanye nokuhlaziywa kwezidingo

1. Imininingwane ye-Billet: 150mm×150mm×12000mm

2. The izinga lokushisa lokuqala I-billet: 850 ℃ (izinga lokushisa eliyisisekelo lingaphezu kwezinga lokushisa elingaphezulu)

3. Izinga lokushisa lokugcina le-billet: ≥1050℃

4. Imfuneko yokuphuma: 60t/h

B. Imingcele yezobuchwepheshe

Ngokwezidingo zokwenyuka kwezinga lokushisa nokubalwa kokukhiqiza, amandla okufudumeza alungiswa ngamandla angu-5000KW, ukulungiswa kwe-pulse engu-12, kanye nemvamisa yesikhungo sokuklama engu-500HZ. Umthamo we-transformer ngu-5000KVA. Ukuze kuqinisekiswe umehluko wokushisa phakathi kwengqikithi nendawo, ukufudumeza kwe-3-stage kuyamukelwa, okungukuthi, ama-heater angu-3 amisiwe. I-billet ihanjiswa ngama-pinch roller angu-4. Ingaphambili le-heater yokuqala ifakwe i-roller yokudla yokucindezela amandla ukulawula isivinini nesiqondiso; ngemuva kwe-heater yesithathu ifakwe i-roller ye-pressure feed feed, kanti phakathi kukhona ama-pinch rollers angenawo amandla. I-pinch roller isebenzisa ukulawulwa kwesivinini sokuguqulwa kwemvamisa, futhi isivinini somugqa esiphezulu kufanele sihlangabezane nezimfuneko zevolumu yokudlulisa i-billet.

Uhlelo lokulawula lukhetha imodyuli yokulawula ye-Siemens S7-200, futhi isebenzisa ama-thermometer ensimbi angu-2 we-infrared ukuze ahlukanise isilinganiso sokushisa kanye nesampula ye-billet inlet kanye ne-billet outlet. Isignali yokutholwa kwesikhathi sangempela ithunyelwa kusistimu yokulawula ukuze ibone ukulinda okuzenzakalelayo kwamandla aphansi wesistimu yokushisa ngaphandle kwezinto ezibonakalayo , Inomsebenzi wokulinganisa izinga lokushisa nokulawula isivinini ukuze kuncishiswe ukulahlekelwa okungadingekile nokwandisa ukusetshenziswa kahle kwamandla. Isignali yezinga lokushisa izolawulwa ngokuzenzakalelayo izinga lokushisa le-PID, futhi ukunikezwa kwamandla okuvama okumaphakathi kuzonciphisa ngokuzenzakalelayo amandla okufinyelela ukugcinwa kokushisa lapho izinga lokushisa elimisiwe lifinyelelwa, futhi izinga lokushisa lokushisisa ngeke libe phezu kwezinga lokushisa noma ngaphansi kwezinga lokushisa.