- 28

- Dec

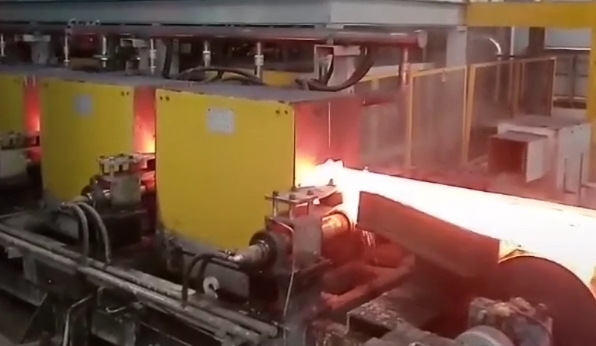

Billet online induction heating furnace

Billet online induction heating furnace

A. User’s existing conditions and needs analysis

1. Billet specifications: 150mm×150mm×12000mm

2. The initial temperature of the billet: 850℃ (the core temperature is higher than the surface temperature)

3. Final temperature of billet: ≥1050℃

4. Output requirement: 60t/h

B. Technical parameters

According to temperature rise requirements and production calculations, the heating power supply is configured with a power of 5000KW, 12-pulse rectification, and a design center frequency of 500HZ. The transformer capacity is 5000KVA. In order to ensure the temperature difference between the core and the surface, the 3-stage heating is adopted, that is, 3 heaters are configured. The billet is conveyed by 4 pinch rollers. The front of the first heater is equipped with a power pressure feed roller to control the speed and guidance; the back of the third heater is equipped with a power pressure feed roller, and the middle is Non-powered pinch rollers. The pinch roller adopts frequency conversion speed regulation, and the maximum linear speed should meet the requirements of the billet conveying volume.

The control system selects Siemens S7-200 control module, and uses 2 infrared metal thermometers to divide the temperature measurement and sampling of the billet inlet and the billet outlet. The real-time detection signal is sent to the control system to realize the automatic low-power standby of the heating system without material , It has the function of temperature measurement and speed regulation to reduce unnecessary losses and maximize energy efficiency utilization. The temperature signal will be automatically controlled by PID temperature, and the intermediate frequency power supply will automatically reduce the power to achieve heat preservation when the set heating temperature is reached, and the heating temperature will not be over-temperature or under-temperature.