- 03

- Sep

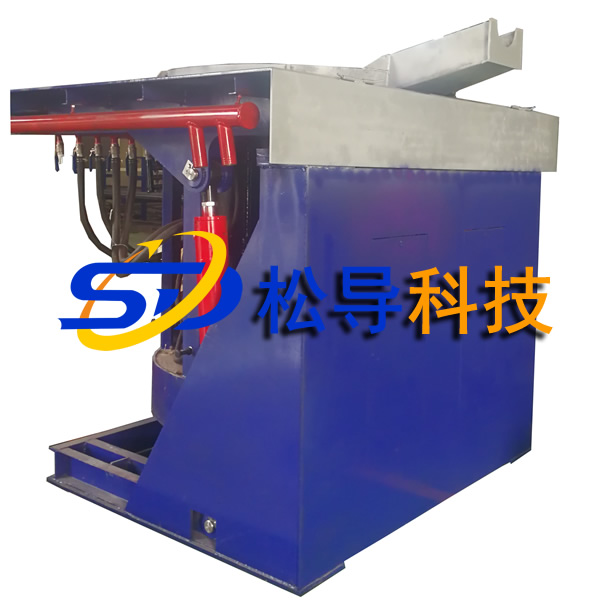

Insimbi yegobolondo lesisindo esiphakathi nendawo

Insimbi yegobolondo lesisindo esiphakathi nendawo

A. Liyini igobolondo lensimbi eliphakathi nemvamisa yesithando?

Ukwakheka kwensimbi kuncibilikisa isithando somlilo nge-hydraulic cylinder njengoba isithando somlilo saziwa kakhulu njengegobolondo lensimbi eliphakathi nendawo lesithando somlilo. Igobolondo lensimbi eliphakathi nendawo imvamisa yesithando somlilo ikakhulu lifaka phakathi: ifreyimu yesithando esivaliwe, ikhoyili ye-inductor, ijoka, ikhava yesithando, uhlelo lokususa uthuli, isilinda esitshekile, ikhava yomlilo ejikeleza isilinda, ipayipi elingena-carbon elingenayo ingcindezi, umlomo wesithando somlilo kanye nesithando somlilo esithululela izinto ezihleliwe, iqoqo eligcwele lensimbi engenalutho esabalalisa amanzi, umqoqi wamanzi obuyayo, uqinisa, itheku lamanzi kanye nendawo yokuhlukanisa amanzi engagqwali, njll.

- Insimbi yegobolondo eliphakathi nendawo ukukhethwa kwentengo yesithando somlilo

| imodeli | Intengo yesikhumba segobolondo eliphakathi nendawo | |||||||

| Amandla wokulinganisa (KW) |

voltage Input (V) |

Isikhathi sokukha amanzi (T / h) |

Amanzi Ukusetshenziswa (T / h) |

ukusetshenziswa kwamandla (Kw / T | voltage (V) |

umthamo (T) |

Inani eliphelele | |

| I-GWG-0.5T | 400 | 660 | 0.5 | 10 | 720 | 800 | 0.5 | Ingqikithi: ¥ 148800RMB |

| I-GWG-0.75T | 600 | 660 | 0.9 | 12 | 630 | 2700 | 0.75 | Ingqikithi: ¥ 168800RMB |

| I-GWG-1 T | 800 | 380-660 | 1 | 18 | 630-600 | 1400-2500 | 1 | Ingqikithi: ¥ 221000RMB |

| I-GWG-1.5T | 1200 | 380-660 | 1.5 | 22 | 630-600 | 1400-2500 | 1.5 | Ingqikithi: ¥ 230000RMB |

| I-GWG-2T | 1600 | 380-660 | 2 | 28 | 600-550 | 1400-2500 | 2 | Ingqikithi: ¥ 361500RMB |

| I-GWG-3T | 2000 | 660-1000 | 3 | 35 | 600-530 | 2300-5000 | 3 | Ingqikithi: ¥ 447000RMB |

| I-GWG-5T | 3000 | 660-1000 | 5 | 45 | 600-530 | 2300-5000 | 5 | Ingqikithi: ¥ 643000RMB |

| I-GWG-6T | 3500 | 660-1000 | 6 | 50 | 600-530 | 2500-5000 | 6 | Ingqikithi: ¥ 743000RMB |

| I-GWG-7T | 4000 | 660-1000 | 7 | 55 | 600-530 | 2500-5000 | 7 | Ingqikithi: ¥ 843000RMB |

| I-GWG-8T | 5000 | 660-1000 | 8.5 | 65 | 600-530 | 2700-5000 | 10-15 | Ingqikithi: ¥ 940000RMB |

C. Ungasikhetha kanjani isakhiwo sensimbi yegobolondo eliphakathi nendawo lesithando somlilo?

1. Uhlaka lwensimbi oluvaliwe lwesakhiwo segobolondo lensimbi Lesisemkhatsini imvamisa esithandweni kulula ukugcinwa nokulungiswa kwansuku zonke; insimbi yesiteshi ifakwe phakathi esakhiweni esiyisisekelo sefreyimu yesithando somlilo, isakhiwo sonke silula futhi siqinile, futhi i-engeli enkulu yokuthambekela komzimba esithandweni ingama-95 degrees.

2. Ubuso begobolondo lensimbi eliphakathi nendawo lamapulatifomu wesithando somlilo bunezinto zokwakha ezingavikela umzimba, ezingavikela umzimba wesithando ngokugcwele futhi ipulatifomu yesithando somlilo ngeke ikhubazeke.

3. Isakhiwo sensimbi siboshelwe esithandweni segobolondo lensimbi esiphakathi, esinezixhaso ezifanele kanye nezingxenye zokuqinisa ukulungisa ikhoyili yesithando somlilo kanye nejoka; ingxenye ephezulu yesithando sokungeniswa iyatholakala, ukuze kube lula ukufaka esikhundleni sekhoyili.

4. Izinsimbi zensimbi ezisindayo ezinhlangothini zombili zensimbi yegobolondo eliphakathi nezinsika zesithando somlilo ziba ukusekelwa okuqinile komzimba wesithando somlilo, zinikeze i-axis eguqulayo ye-axis, futhi i-eksisi iya ngaphandle nangaphezulu. Qinisekisa umkhondo wokunyakaza omncane wombhobho wokuthepha, ukunciphisa ukunciphisa ukulahleka kwamandla kwamandla, futhi wenze lula amadivayisi wokuxhuma wensimbi othomathikhi futhi aqondile ukuthola insimbi encibilikisiwe.

5. Ikhoyili yokungeniswa kwesikhumba segobolondo eliphakathi nendawo esivame ukuhlangana lihlanganiswe ngamapayipi wethusi aqinile futhi ahlala isikhathi eside. Ikhoyili epholile ngamanzi kanye nekhoyili esebenza kahle kulinyazwa ngamapayipi ethusi. Ukuphenduka okubili kwekhoyili yokungeniswa ngaphandle kokuhlukaniswa kuvinjelwe ngokuqinile phakathi kwamapayipi wethusi aseduze futhi ubuchwepheshe obusezingeni eliphakeme bokuhlukaniswa buyamukelwa. Amashidi wokuvikela afakwa phakathi kwamakhoyili wokungeniswa aseduze, futhi amakhoyili afakwa ngumoya. Ngemuva kokuthi upende ufuthwe, uba yisakhiwo esiphelele futhi ucindezelwe yizakhiwo zensimbi ezingenhla nezingezansi emzimbeni womlilo. Isakhiwo sisonke siqinile futhi asinankinga yokukhubazeka. Inani lokujika kwegobolondo lensimbi eliphakathi nendawo lekhoyili yesithando kufanelekile ukufeza ukusebenza kahle kwamandla kagesi. Ishubhu yethusi yekhoyili yokungeniswa yiphubhu yethusi engenawo umoya-mpilo ekhiqizwa nguChinalco Luotong, enokuhlanzeka kwe-0.99 kanye nokuqhuba okungaphezulu kwe-100; ikhoyili ipholile yimigudu yamanzi eminingi. Sabalalisa amanzi ngokulinganayo. Ingaphandle lekhoyili lilimale ngokuqinile ngezinto ezivimbayo. I-gasket yokuvikela i-arc emise phakathi kokujika nayo iqinisekisa ukuhlukaniswa kwamakhoyili afanayo futhi yenza lula ukugeleza komswakama.

6. Upende wokufaka we-coil yokufakwa we-shell yegobolondo yensimbi emaphakathi yesithando somlilo sisebenzisa upende woqweqwe lwawo wokubhaka ongenisiwe. Ngemuva kwezikhathi ezi-5 zokufafaza nokubhaka, izinga lokufakwa lingafinyelela ezingeni lika-H.

7. Ijoka le-shell yegobolondo lensimbi eliphakathi nendawo imvamisa yomlilo ligcizelelwa ngokulinganayo ngamabhawodi wesitimela futhi linikeza amandla amakhulu okubamba ikhoyili ukuqinisekisa impilo ende yokusebenza komugqa wesithando somlilo. Ijoka lenziwe ngosayizi wensimbi eyakhiwe ngamakhaza ashubile ano-0.35mm. Ngemuva kokucubungula ishidi lensimbi le-silicon, ukubekezelelana kwe-flash cut cut is <± 0.1mm. Izinga lokugoba kwegobolondo lensimbi ngemuva kokuhlanganiswa kwesithando semvamisa esiphakathi, futhi ukufana kuqinisekisa i-arc yekhoyili nejoka Njengokuxhumana, i-lotus coupling. Ngasikhathi sinye, amasethi amaningi wamadivayisi wokubopha amajoka aqinile futhi athembekile, kulula ukuwahlanganisa, ukuwaqaqa, ukuwalungisa, nokuwalungisa, futhi asatshalaliswa ngokulinganayo esiyingini (iphutha -0.5); i-liner phakathi kwejoka kanye nekhoyili yenziwa ngezendlalelo eziningi zezinto ezisezingeni eliphakeme zokuvikela izinto, kufaka phakathi izingqimba eziningi ze-Mica board, multilayer ceramic fiber board.

8. Ingaphezulu nesansi segobolondo lensimbi Lesisemkhatsini imvamisa isithandelo sinamabhodi okwakha ukushisa okwakhiwe namasongo wesikhashana.

9. Uhlelo lokuvikelwa kokuvuza kwegobolondo lensimbi Lesisemkhatsini imvamisa esithandweni luphephile futhi luthembekile. Lapho insimbi encibilikisiwe ihlasela noma isizongena ezintweni ezikhanyisayo namakhoyili, izonqamula amandla ngokuzenzakalela bese inika i-alamu. Uhlelo lokuvikela ukuvuza kwesithando somlilo luyingxenye ebalulekile yohlelo lonke lokuvikela isithando somlilo.

D. Ziyini izinzuzo zensimbi yegobolondo eliphakathi nemvamisa yesithando?

I-1) Imangele, iqine futhi yinhle, ikakhulukazi umzimba wesithando somthamo omkhulu, odinga isakhiwo esiqinile esiqinile. Ngokombono wokuphepha kwesithando somlilo esivivinya umzimba, zama ukusebenzisa igobolondo lensimbi eliphakathi nendawo lesithando somlilo.

I-2) Ijoka elenziwe ngezihlangu zeshidi lensimbi le-silicon futhi likhipha imigqa kazibuthe eyenziwe ngekhoyili yokungeniswa, inciphisa ukuvuza okugeleza ngamandla, ithuthukise ukusebenza kahle kokushisa, inyuse okukhiphayo, futhi isindise cishe i-5% -8%.

3) Ukuba khona kwesembozo sesithando kunciphisa ukulahleka kokushisa futhi kuthuthukisa nokuphepha kwemishini.

I-4) Impilo yensizakalo ende, igobolondo lensimbi eliphakathi nendawo imvamisa isithando somlilo sinokuvuza okuncane okunamandla kazibuthe, futhi impilo yesevisi yemishini yinde kakhulu kune-aluminium esithandweni somlilo. Ngokuvamile, impilo yesevisi ejwayelekile ingaphezu kweminyaka eyi-10.

I-5) Ukusebenza kokuphepha kwegobolondo lensimbi eliphakathi nendawo imvamisa esithandweni kungcono kakhulu kunesithando somlilo se-aluminium. Lapho isithando somlilo se-aluminium sincibilika ngenxa yokushisa okuphezulu nengcindezi esindayo, igobolondo le-aluminium likhubazeka kalula futhi ukuphepha kubi. Igobolondo lensimbi eliphakathi nendawo lesithando somlilo lisebenzisa isithando somlilo esibheke phezulu, esiphephile futhi esithembekile.

E. Yikuphi ukusetshenziswa okuyinhloko kwezinsimbi zegobolondo lensimbi eliphakathi nendawo?

Igobolondo lensimbi eliphakathi nendawo lesithando somlilo lisetshenziselwa ukuncibilikisa insimbi, insimbi, ithusi, i-aluminium kanye nama-alloys. Inezici zokuncibilika okuphezulu, ukusebenza kahle kwamandla okusindisa, ukwakheka kwensimbi okufanayo, ukulahleka okuncane kokushisa, ukukhuphuka kokushisa okusheshayo, nokulawula okushisa okulula. Ifanele okuhlukahlukene I-metal iyancibilika.

F. Iyini indima yejoka kazibuthe egobolondweni lensimbi Lesisemkhatsini imvamisa esithandweni?

Ijoka ijoka elenziwe ngamashidi wensimbi enamathele. Ihlukaniswe ngokulingana nangokulingana ngokulingana nekhoyili yokungeniswa. Umsebenzi wawo ukuvimbela ukuvuza kwekhoyili lokungeniswa ukuthi lisabalale, kuthuthukise ukusebenza kahle kokungeniswa futhi kungezwe abantu, futhi kulinciphise njengehawu likazibuthe Ukushisa kwezinsimbi zensimbi njengohlaka lwesithando somlilo nakho kudlala indima ekuqiniseni i-inductor.

Isithando segobolondo lensimbi esiphakathi nendawo sinejoka lamagnetic elakhelwe ngaphakathi, futhi ukuvikelwa kwejoka kazibuthe kunganciphisa ukuvuza kwamandla kazibuthe, kuvimbele isithando ekushiseni, futhi kuthuthukise ukusebenza kahle. Ngasikhathi sinye, ijoka lidlala indima yokuxhasa nokulungisa ikhoyili yokungeniswa, ukuze umzimba wesithando somlilo ukwazi ukuthola amandla aphezulu nomsindo ophansi.

G. Siyini isizathu sokushisa okuphezulu kwejoka lensimbi yegobolondo eliphakathi nendawo lesithando somlilo?

Ijoka elibomvu yinto ejwayelekile yamaphutha ekusebenzeni kokuphakelwa kwamandla kagesi okuphakathi. Okokuqala hlola ukuthi ngabe ikhona yini inkinga ngohlelo lwamanzi okupholisa, hlola ukuthi ngabe amanzi angena noma aphuma ejokeni elibomvu ajwayelekile yini nokuthi ipayipi liyaguga futhi liyavuza yini. Uma kujwayelekile, bese uhlola izici ezilandelayo.

(1) Ijoka lokunikezwa kwamandla okuphakathi okuphakathi ukuguga, futhi ukumbozwa kokufakwa phakathi kwezingqimba kudliwe kakhulu. Ngenxa yalokhu, ishidi lensimbi le-silicon lingavulelwa ukwelashwa kwendawo yokumboza.

(2) Ijoka libhajwe ngensimbi encibilikisiwe (ukufakwa kwensimbi). Ngenxa yalokhu, ijoka lingapholishwa ukuze kususwe ukufakwa kwensimbi okubhajwe.

(3) Hlola ukushuba kwaphansi kwesithando somlilo. Uma ingaphansi lesithando somlilo likhulu kakhulu, kuzodala ukuthi ijoka lishise libe bomvu.

(4) Izinga lokushisa lomgudu wamanzi ojikelezayo liphezulu kakhulu, futhi izinga lokushisa lamanzi langaphakathi lohlelo lokusakazwa kwejoka liphakeme kakhulu ukukhiqiza igesi. Ngenxa yokuthi igesi ayikwazi ukukhishwa, amanzi ajikelezayo awakwazi ukujikeleza, okwenza izinga lokushisa likhuphuke.

(5) Ngemuva kokuthi umfutho wamanzi ojikelezayo uba mncane noma kuguqulwe indlela yamanzi, indlela yamanzi iba ningi noma ipayipi lamanzi liba likhulu, nokugeleza kwamanzi kwamanye amasekethe kukhule, kubangele ukugeleza kwamanzi ejoka kwehle.