- 07

- Dec

Heating process of copper tube induction continuous annealing production line

Heating process of copper tube induction continuous annealing production line

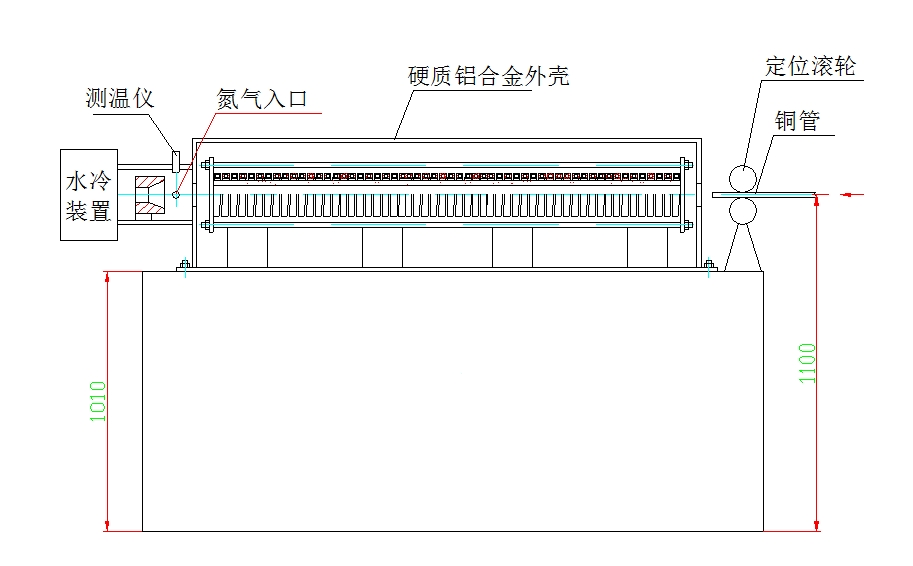

The required power supply 400KW/6KHZ is used to supply power to the two heating furnace bodies. The two heating furnace bodies heat the copper pipes. After each furnace body performs a rapid temperature increase on the copper pipes, after a short heat preservation process, this process is There is no heating process, in order to prevent the copper tube from lowering its head and unable to align when entering the next induction furnace, there is a mechanical roller device in the middle for positioning; in order to prevent oxidation of the copper tube heating process, two furnace bodies and guide parts are installed in one In a sealed shell, inert gas is introduced into it; the length of each furnace body is 400MM, the distance between the mechanical roller device and the furnace body is 20MM on one side, and the total length of the furnace body is 800MM. Consider the shell occupies part of the space , The total length of the heating part needs to be 1200MM.

The two furnace bodies and a set of mechanical roller device bases are fixed on the same furnace body base. The shell of the furnace body is hard copper alloy, which can simultaneously play a protective gas sealing and magnetic shielding function, so that the frame, rollers, etc. It is not heated by magnetic flux leakage induction; the furnace shell is designed to be detachable, which provides convenience for the maintenance of the furnace body and the replacement of the mechanical roller device.

Schematic diagram of part of the furnace body equipment (Figure 1)

https://songdaokeji.cn/13909.html

https://songdaokeji.cn/13890.html