- 05

- Sep

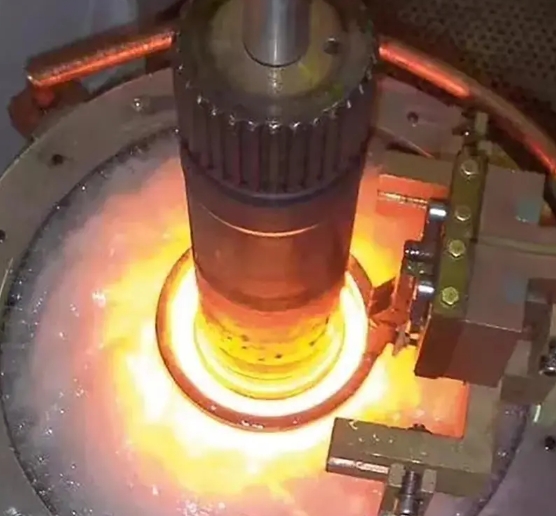

The following aspects need to be paid attention to when purchasing a high-frequency furnace sensor

The following aspects need to be paid attention to when purchasing a high-frequency furnace sensor

1) Appearance and geometric dimension inspection. The focus is on the main dimensions of the effective ring, diameter and width, fillet radius, center height, the matching size of the contact plate, the perpendicularity between the contact plate and the end face of the effective ring, and the parallelism with the center line of the effective ring, etc.

2) Weld quality. Check whether there is leakage when the test pressure reaches the required pressure. It must be done strictly according to the drawing requirements.

3) Whether the angle of the spray hole meets the requirements, and whether the spray hole is blocked by welding overflow.

4) Whether the standard parts are complete and whether the nuts are tightened (key parts can be marked with red paint if necessary).

5) Flow test. Especially for sensors with small pipe cross-sectional area, flow test is very necessary.

6) Whether the surface of the contact board is smooth and clean, no pits, bumps, scratches and other defects are allowed. For the conical contact surface, the taper angle and surface roughness required by the drawing should be guaranteed, and the contact surface should not have adhesive and insulating paint.

7) The radial and axial clearance between the effective ring of the half-ring type crankshaft sensor and the workpiece should be checked with a special mandrel and a feeler gauge.

8) For high-frequency furnace inductors with many accessories, use a multimeter or a 500V insulation resistance meter to check whether the conductive parts such as the effective ring are in contact with other metal parts.

9) Whether the necessary marks have been printed on the high-frequency furnace sensor, such as the main size or drawing number of the effective ring.

10) When the sensor is equipped with a quick-change pipe joint, it should be matched with the pipe cap to check whether it is properly matched.

11) For the small inner hole heating sensor, the pipe joint passing through the central conductive pipe is the water inlet, and it is best to mark it to prevent wrong connection when taking over.

12) In addition to the contact surface, the sensor should be coated with protective paint, and insulating varnish is one of the applicable paints.