- 13

- Sep

Reasons for continuous casting of argon-blown and breathable brick ladle after refining

Reasons for continuous casting of argon-blown and breathable brick ladle after refining

After the molten steel in the ladle is continuously blown with argon to complete the refining, there will be continuous casting. The role of continuous casting is to continuously cast the refined molten steel to produce the final product of steelmaking: qualified steel ingots or billets.

After the molten steel in the ladle is continuously blown with argon to complete the refining, there will be continuous casting. The role of continuous casting is to continuously cast the refined molten steel to produce the final product of steelmaking: qualified steel ingots or billets.

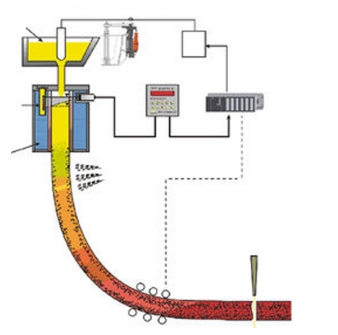

The ladle receives the molten steel produced from the converter, and then is refined by argon blowing through the air-permeable brick, and then cast into a billet of the corresponding shape according to the production process and requirements of the steel plant. The main equipment of the continuous casting section includes turntable, tundish, crystallizer, cooling nozzle, flame cutter, etc.

(Picture) The composition of continuous casting

The quality of steel ingots or billets has a lot to do with the smoothness of the continuous casting process. The steps of continuous casting are as follows: After refining, the ladle of argon-blown air-permeable bricks is transported to the turntable. After the turntable rotates to the pouring position, the molten steel is injected into the tundish, and then the molten steel is distributed to each mold through the nozzle . The mold is one of the core equipment of the continuous casting machine. It is a forced water-cooled bottomless steel ingot mold that can quickly shape the molten steel. The main function of the mold vibrating device is to make the mold reciprocate up and down, which facilitates demolding. The tension leveler has the same function as the crystal vibration device. It can cut the castings drawn out of the crystallizer into a certain length of slab after cooling and electromagnetic stirring.

(Picture) Trajectory of molten steel

The ladle of argon-blowing and breathable bricks is refined and then continuously casted. This is the main way for steel mills to produce products, and it is also the main way for steel mills to achieve their goals. firstfurnace@gmil.com has served steel mills for more than ten years, specializing in the production of breathable bricks, nozzle block bricks, electric furnace covers, etc., with patented formulas and unique designs, which continue to help the steelmaking industry.