- 16

- Sep

Analysis of the characteristics of diffuse air-permeable bricks

Analysis of the characteristics of diffuse air-permeable bricks

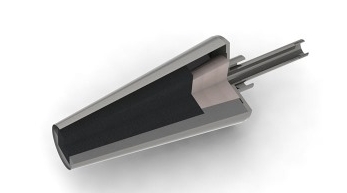

The new diffuse ventilated bricks have the characteristics of their microstructures, so that the original slit ventilated bricks often show the slits and the steel to form the bottom blowing impermeable or undesirable phenomenon. When the slit-type ventilating brick is working and ventilating, the cold air flows in the slit to generate a large temperature gradient, and part of the thermal stress that occurs is concentrated near the slit. In particular, the thermal stress at the air outlet of the slit is greater, making the slit in use The size changes during the process, causing the molten steel to simply invade the slits, resulting in impenetrable bottom blowing or undesirable phenomena. In addition, if the bottom blowing valve is quickly closed after the essence is completed, the molten steel will enter the slit at a positive pressure, so it is necessary to install a reverse impregnation one-way stop valve on the argon blowing pipeline. Therefore, slit-type air-permeable bricks must have suitable and stable slit air passage sizes and materials with good thermal stability to reduce the slitting of steel. The air permeable channel of the diffuse air-permeable brick is a large number of connected and visible pores dispersed in the brick body (as shown in Figure 2). These micron-level curved channels form a relatively large resistance to the penetration of molten steel, and are basically non-penetrating in actual use. , The air bubbles generated by the diffused air-permeable brick are small, uniform and dense, it is easier to stir the molten steel to a uniform temperature, and it is easier to promote the floating of inclusions to achieve a better essence effect.

The new diffused air-permeable brick is not prone to cross-section of the brick core. Ordinary slit type air-permeable bricks are in direct contact with the high-temperature molten steel at the slit air outlet when the argon is blown, and the cold air flow continues to flow out, resulting in a large temperature gradient, resulting in a very large thermal stress at the slit air outlet, plus the use of In the process, the effect of rapid cold and hot heat, which is close to the slit air outlet, simply crosses, which causes the slit to shift and the bottom blow is impenetrable. The thermal stress caused by the volumetric expansion of other parts during the temperature drop and the temperature rise can easily form a slit-type air-permeable brick to cross-fault, which puts forward higher requirements for the thermal shock resistance and stability of the refractory material. However, there are micron gas channels on the entire working surface of the dispersive ventilating brick, and the temperature gradient of the working surface is small, so that the new dispersive ventilating brick is not prone to cross-section of the brick core.