- 15

- Feb

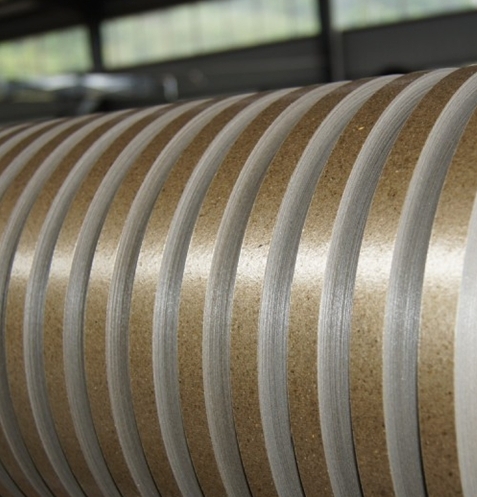

Mica board special-shaped processing method

Glimmerplade specialformet behandlingsmetode

1. Boring

Dette er en almindelig behandlingsmetode i printkortfabrikker. Uanset om det er PCB-testarmaturer eller PCB-efterbehandling, vil de gennemgå “boring”. Større PCB-fabrikker indretter normalt deres egne borerum, som normalt sammenlignes med inventar. Tæt på, og arbejdet i borerummet er ikke et let arbejde, men det er relativt gratis. Normalt er forbrugsmaterialer og udstyr, der bruges i borerummet, specielle borerigge, boredyser, gummipartikler, træbagplader, aluminiumsbagplader osv.

In addition, the common way of drilling is the new LED lampshade-retaining insulation. As an energy-saving industry, LED has been hailed in recent years, and LED is composed of many small lamps. This feature makes the application field of insulation board broaden again. , Generally, the processing method of LED-retained insulating parts is to drill a hole and then gong a circle. The processing method is relatively simple and the market is huge.

2. Computer gongs

Generally speaking, it is CNC or numerical control, and it is also called a machining center. In fact, they all mean the same thing. The function of the computer gong is very powerful. The surface is divided into plane and inclined plane (or called curved surface). The category of inclined plane is relative. The computer gongs are much smaller, and the flat computer gongs are very extensive. Small processing parts such as insulating gaskets, insulating rods, and star wheels are all processed by computer gongs to process epoxy boards. The biggest feature of computer gongs is flexibility, speed, and function. Powerful, is currently the best and most commonly used processing method.

3. Opskæring

This is a common and common processing method in the market. The general store has a cutting machine to cut the plates, and this is usually relatively rough, and the tolerance can be controlled within 5mm.

4. Fræsemaskine/drejebænk

Produkterne, der forarbejdes ved denne forarbejdningsmetode, er normalt produkter såsom dele, fordi fræsemaskiner og drejebænke for det meste bruges til bearbejdning af hardwaredele, men den langsomme forarbejdningshastighed for almindelige fræsemaskiner og drejebænke er en væsentlig egenskab, så hvis du udelukkende stoler på denne form for epoxypladebehandlingsmetode, vil virksomhedens levetid blive stærkt reduceret, men hvis du laver en jig, er disse to typer udstyr uundværlige.