- 15

- Feb

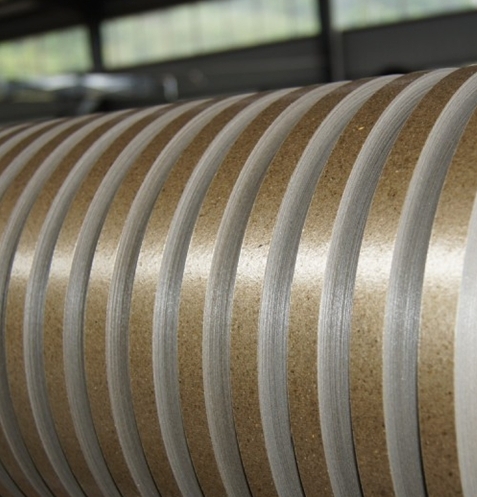

Mica board special-shaped processing method

Mica board special-shaped rêbaza pêvajoyê

1. Drilling

This is a common processing method in PCB circuit board factories. Whether it is PCB test fixtures or PCB post-processing, they will go through “drilling”. Larger PCB factories usually set up their own drilling rooms, which are usually compared with fixtures. Close, and the work in the drilling room is not an easy job, but it is relatively free. Usually the consumables and equipment used in the drilling room are special drilling rigs, drill nozzles, rubber particles, wooden backing plates, aluminum backing plates, etc.

In addition, the common way of drilling is the new LED lampshade-retaining insulation. As an energy-saving industry, LED has been hailed in recent years, and LED is composed of many small lamps. This feature makes the application field of insulation board broaden again. , Generally, the processing method of LED-retained insulating parts is to drill a hole and then gong a circle. The processing method is relatively simple and the market is huge.

2. Computer gongs

Generally speaking, it is CNC or numerical control, and it is also called a machining center. In fact, they all mean the same thing. The function of the computer gong is very powerful. The surface is divided into plane and inclined plane (or called curved surface). The category of inclined plane is relative. The computer gongs are much smaller, and the flat computer gongs are very extensive. Small processing parts such as insulating gaskets, insulating rods, and star wheels are all processed by computer gongs to process epoxy boards. The biggest feature of computer gongs is flexibility, speed, and function. Powerful, is currently the best and most commonly used processing method.

3. Çirandin

This is a common and common processing method in the market. The general store has a cutting machine to cut the plates, and this is usually relatively rough, and the tolerance can be controlled within 5mm.

4. Maşîneya makîneyê/tûrê

The products processed by this processing method are usually products such as parts, because milling machines and lathes are mostly used for processing hardware parts, but the slow processing speed of ordinary milling machines and lathes is a major feature, so if If you rely exclusively on this kind of epoxy board processing method, the life of the company will be greatly reduced, but if you are making a jig, these two types of equipment are indispensable.