- 25

- Oct

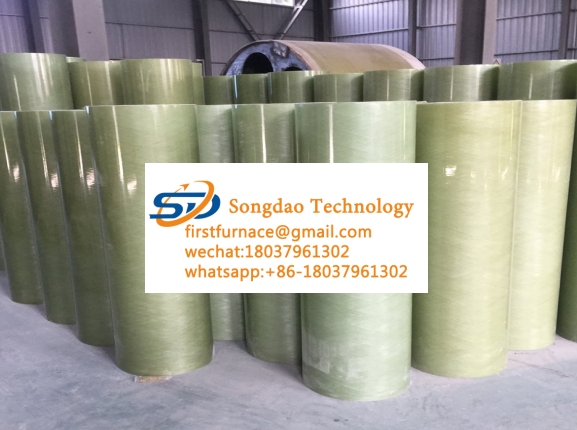

Performance parameter table of epoxy glass fiber wound insulation cylinder

Performance parameter table of epoxy glass fiber wound insulation cylinder

Product use: Widely used in the main insulators of high-voltage products such as oil-immersed transformers, H-class dry-type transformers, railway locomotive transformers, on-load tap-changers, reactors, arresters, SF6 transformers, and test devices.

Caractéristiques :

1. High withstand voltage

2. Faible perte diélectrique

3. The partial discharge is small

4. Haute résistance mécanique

5. No deformation and no delamination

6. Very low water absorption

7. Chemical resistance (SF6 resistance)

Product specifications: the inner diameter of the insulating cylinder ranges from Φ6mm to Φ2480mm, the wall thickness of the small tube is ≥0.5mm, the wall thickness of the large tube is ≥3mm, the wall thickness of the super-large tube is ≥5mm, and the length is within the length of the core mold. Our company has more than 400 sets of molds ranging from Φ6mm to Φ2480mm. (For specific specifications, please refer to the core mold specification table). Special specifications will be negotiated separately.

Avis de commande:

1. All users, please try to apply the existing mandrel specifications, such as the cost and time of redo mandrel.

2. Because the production process has a period of time and the specifications of each user are different, please order in advance.

Performance parameter table of Class H epoxy fiberglass insulation cylinder

| Non | Nom de l’indicateur | Nos Exigences | Unité | Valeur d’index |

| 1 | Densité | G / cm3 | 1.9-2.0 | |

| 2 | Intensity of bending | Pas moins que | Mpa | 320 |

| 3 | Pressure resistance strength | Pas moins que | Mpa | 200 |

| 4 | Résistance anti-cisaillement | Pas moins que | Mpa | 32 |

| 5 | Medium Loss Factor (50Hz) | No greater than | 0.02 | |

| 6 | La constante diélectrique | 3 ~ 6 | ||

| 7 | When the volume resistivity is normal | Pas moins que | Qm | un suivi h10 |

| After immersion | un suivi h10 | |||

| 8 | When the parallel layer moves toward the normal insulation resistance | Pas moins que | Q | un suivi h10 |

| After immersion | un suivi h10 | |||

| 9 | Surface voltage resistance

(Pressure-resistant lmin,30mm in the air) |

KV | 14 | |

| 10 | Vertical layer direction resistance voltage of 8> 3mm | KV | 20 | |

| 11 | Parallel layer-resistant voltage (25mm spacing) | Pas moins que | KV | 50 |

| 12 | La resistance d’isolement | Pas moins que | MQ | un suivi h5 |

| 13 | Industrial frequency voltage resistance distance (by customer technology

Exigences) |

Pas moins que | KV | 80 |

| 14 | Résistance à la chaleur | Pas moins que | ° C | 180 |

| 15 | Meverage thermal deformation temperature | Pas moins que | ° C | 250 |