- 25

- Oct

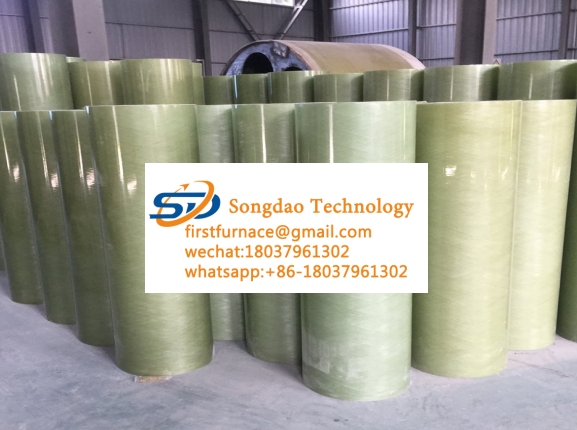

Performance parameter rooj ntawm epoxy iav fiber ntau qhov txhab rwb thaiv tsev lub tog raj kheej

Performance parameter rooj ntawm epoxy iav fiber ntau qhov txhab rwb thaiv tsev lub tog raj kheej

Kev siv khoom: Siv dav hauv cov khoom siv hluav taws xob loj xws li cov roj hloov pauv, H-chav hloov pauv qhuav, hloov pauv tsheb ciav hlau, hloov pauv ntawm lub tshuab hloov pauv, reactors, ntes, SF6 hloov pauv, thiab ntsuas cov cuab yeej .

nta:

1. High withstand voltage

2. Tsawg dielectric poob

3. Qhov tso tawm ib nrab yog me me

4. Muaj zog kho tshuab

5. Tsis muaj deformation thiab tsis muaj delamination

6. Kev nqus dej tsawg heev

7. Tshuaj tiv thaiv (SF6 tsis kam)

Cov khoom tshwj xeeb: sab hauv txoj kab uas hla ntawm lub tog raj kheej insulating yog los ntawm mm6mm txog 2480mm, phab ntsa tuab ntawm lub raj me yog ≥0.5mm, phab ntsa tuab ntawm lub raj loj yog ≥3mm, phab ntsa tuab ntawm lub raj loj loj yog ≥ 5mm, thiab qhov ntev yog nyob rau hauv qhov ntev ntawm cov tub ntxhais pwm. Peb lub tuam txhab muaj ntau tshaj 400 txheej pwm xws li Φ6mm txog Φ2480mm. (Rau cov lus tshwj xeeb, thov saib mus rau lub hauv paus txheej txheem txheej txheem pwm). Cov lus tshwj xeeb yuav tau sib tham sib cais.

Tsab ntawv ceeb toom:

1. Txhua tus neeg siv, thov sim siv cov mandrel specifications uas twb muaj lawm, xws li tus nqi thiab lub sij hawm ntawm redo mandrel.

2. Vim tias cov txheej txheem ntau lawm muaj lub sijhawm thiab cov kev qhia tshwj xeeb ntawm txhua tus neeg siv sib txawv, thov xaj ua ntej.

Kev ua haujlwm parameter ntawm Class H epoxy fiberglass rwb thaiv tsev lub tog raj kheej

| Tsis yog | Qhov taw qhia lub npe | uas yuav tsum tau | Tsev | Tus nqi Index |

| 1 | ceev | G / cm3 | 1.9-2.0 | |

| 2 | Kev siv zog ntawm dabtsi yog khoov | Tsis muaj tsawg dua | Mpa | 320 |

| 3 | Siab tiv taus lub zog | Tsis muaj tsawg dua | Mpa | 200 |

| 4 | Anti-shear zog | Tsis muaj tsawg dua | Mpa | 32 |

| 5 | Qhov Nruab Nrab Qhov Nruab Nrab (50Hz) | Tsis ntau tshaj | 0.02 | |

| 6 | Dielectric qhov tsis tu ncua | 3 ~ 6 | ||

| 7 | Thaum lub ntim tiv taus yog ib txwm | Tsis muaj tsawg dua | Qm | 10X1011 |

| Tom qab immersion | 10X109 | |||

| 8 | Thaum cov txheej txheem parallel txav mus rau qhov qub rwb thaiv tsev tsis kam | Tsis muaj tsawg dua | Q | 10X1011 |

| Tom qab immersion | 10X109 | |||

| 9 | Deg voltage kuj

(Siab tiv taus lmin, 30 hli hauv huab cua) |

KV | 14 | |

| 10 | Vertical txheej kev taw qhia kuj voltage ntawm 8> 3mm | KV | 20 | |

| 11 | Parallel txheej-resistant voltage (25mm nrug) | Tsis muaj tsawg dua | KV | 50 |

| 12 | Rwb thaiv tsev kuj | Tsis muaj tsawg dua | MQ | 5X104 |

| 13 | Muaj zaus voltage kuj nyob deb (los ntawm cov neeg siv khoom technology

Yuav tsum muaj) |

Tsis muaj tsawg dua | KV | 80 |

| 14 | Kub tshav kub | Tsis muaj tsawg dua | ° C | 180 |

| 15 | Ntsuas thermal deformation kub | Tsis muaj tsawg dua | ° C | 250 |