- 31

- Dec

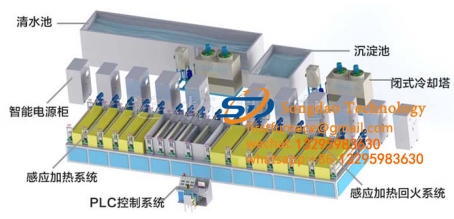

Steel phaj quenching thiab tempering ntau lawm kab

Steel phaj quenching thiab tempering ntau lawm kab

Khoom npe: steel phaj quenching thiab tempering ntau lawm kab

Cov khoom siv ua haujlwm: carbon hlau alloy steel, thiab lwm yam.

Haum rau thickness: ntau dua 5.0mm

Txheej txheem: cua sov, quenching

Qhov kub thiab txias: 900-950 ℃

Lub zog yuav tsum tau muaj: 100-8000 kW

cov steel phaj quenching thiab tempering ntau lawm kab adopts intermediate frequency induction heating power supply control features:

1. Parallel resonance tsim, theem hloov lub zog, lub zog loj, tsis tshua muaj kev sib haum xeeb, thiab kev ua haujlwm yooj yim.

2. Cov khoom siv hluav taws xob thiab cov inductor ib txwm ua kom ntseeg tau qhov sib txuam nrog lub zog tag nrho. Piv nrog rau cov tsoos fais fab inverter, nws tuaj yeem txuag hluav taws xob los ntawm 15-30%.

3. Cov khoom siv hluav taws xob tuaj yeem hloov kho qhov tsis ua haujlwm ntawm cov khoom sib txawv.

4. Kev tswj tag nrho lub vijtsam kov, kev teeb tsa digital ntshiab, ua tiav cov txheej txheem cov ntaub ntawv thiab qib kev tswj hwm nruj. Muaj lub Hoobkas pib dua.

5. Cov hlau phaj quenching thiab tempering ntau lawm kab muaj kev tiv thaiv tus kheej (overcurrent, overpressure, dej siab, theem poob, undervoltage, overload) system. Thaum muaj xwm txheej ceev, cov khoom siv muaj kev kuaj xyuas tus kheej.

钢板淬火和回火生产线

产品名称:钢板淬火和回火生产线

工件材料:碳钢合金钢等

适用于厚度:大于5.0mm

过程:加热、淬火

加热温度:900 – 950℃

功率需要范围:100 – 8000千瓦

钢板淬火和回火生产线采用中频感应加热电源控制特点:

1、并联谐振设计,相移功率,功率因数高,谐波小,操作简单。

2、电源和电感器始终保持与全功率输出的可靠匹配,与传统的电源逆变器相比,节能15-30%。

3、该电源可以自动调节不同尺寸工件的参数。

4、全触摸屏控制,纯数字设置,具有完整的流程记录和严格的权限级别。拥有恢复出厂设置。

5、钢板淬火和回火生产线有自保护(过流、过压、水压、相损耗、欠压、过载)系统,在紧急情况下,设备具有自诊断功能。

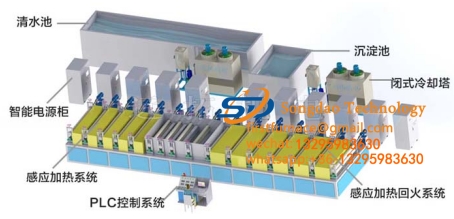

Steel phaj quenching thiab tempering ntau lawm kab

Khoom npe: steel phaj quenching thiab tempering ntau lawm kab

Cov khoom siv ua haujlwm: carbon hlau alloy steel, thiab lwm yam.

Haum rau thickness: ntau dua 5.0mm

Txheej txheem: cua sov, quenching

Qhov kub thiab txias: 900-950 ℃

Lub zog yuav tsum tau muaj: 100-8000 kW

Cov hlau phaj quenching thiab tempering ntau lawm kab txais yuav nruab nrab zaus induction cua sov fais fab mov tswj nta:

1. Parallel resonance tsim, theem hloov lub zog, lub zog loj, tsis tshua muaj kev sib haum xeeb, thiab kev ua haujlwm yooj yim.

2. Cov khoom siv hluav taws xob thiab cov inductor ib txwm ua kom ntseeg tau qhov sib txuam nrog lub zog tag nrho. Piv nrog rau cov tsoos fais fab inverter, nws tuaj yeem txuag hluav taws xob los ntawm 15-30%.

3. Cov khoom siv hluav taws xob tuaj yeem hloov kho qhov tsis ua haujlwm ntawm cov khoom sib txawv.

4. Kev tswj tag nrho lub vijtsam kov, kev teeb tsa digital ntshiab, ua tiav cov txheej txheem cov ntaub ntawv thiab qib kev tswj hwm nruj. Muaj lub Hoobkas pib dua.

5. Cov hlau phaj quenching thiab tempering ntau lawm kab muaj kev tiv thaiv tus kheej (overcurrent, overpressure, dej siab, theem poob, undervoltage, overload) system. Thaum muaj xwm txheej ceev, cov khoom siv muaj kev kuaj xyuas tus kheej.