- 31

- Dec

I-steel plate quenching kanye nomugqa wokukhiqiza wokushisa

I-steel plate quenching kanye nomugqa wokukhiqiza wokushisa

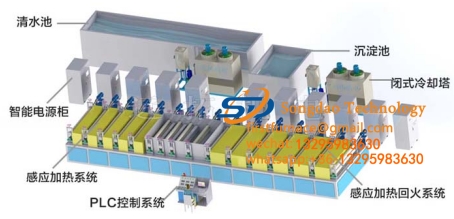

Igama lomkhiqizo: steel plate quenching and tempering production line

Izinto zokwakha: insimbi ye-carbon steel alloy, njll.

Ifanele ukujiya: okukhulu kuno-5.0mm

Inqubo: ukushisa, ukucisha

Ukushisa kokushisa: 900-950 ℃

Ibanga lesidingo samandla: 100-8000 kilowatts

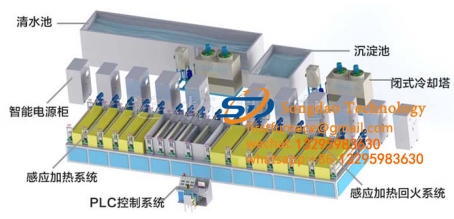

The steel plate quenching and tempering production line adopts intermediate frequency induction heating power supply control features:

1. I-Parallel resonance design, amandla okushintsha kwesigaba, isici samandla aphezulu, ama-harmonics aphansi, nokusebenza okulula.

2. Ukunikezwa kwamandla kanye ne-inductor kuhlala kugcina ukufanisa okuthembekile nokuphuma kwamandla aphelele. Uma kuqhathaniswa ne-inverter yamandla evamile, ingonga amandla ngo-15-30%.

3. Ukunikezwa kwamandla kungalungisa ngokuzenzakalelayo imingcele yama-workpieces osayizi abahlukene.

4. Ukulawula okugcwele kwesikrini sokuthinta, izilungiselelo ezihlanzekile zedijithali, amarekhodi enqubo ephelele kanye namazinga eziphathimandla aqinile. Setha kabusha njengasekuqaleni.

5. I-steel plate quenching kanye nomugqa wokukhiqiza we-temering unokuzivikela (i-overcurrent, i-overpressure, ingcindezi yamanzi, ukulahlekelwa kwesigaba, i-undervoltage, i-overload) uhlelo. Esimeni esiphuthumayo, okokusebenza kunomsebenzi wokuzixilonga.

钢板淬火和回火生产线

产品名称:钢板淬火和回火生产线

工件材料:碳钢合金钢等

适用于厚度:大于5.0mm

过程:加热、淬火

加热温度:900 – 950℃

功率需要范围:100 – 8000千瓦

钢板淬火和回火生产线采用中频感应加热电源控制特点:

1、并联谐振设计,相移功率,功率因数高,谐波小,操作简单。

2、电源和电感器始终保持与全功率输出的可靠匹配,与传统的电源逆变器相比,节能15-30%。

3、该电源可以自动调节不同尺寸工件的参数。

4、全触摸屏控制,纯数字设置,具有完整的流程记录和严格的权限级别。拥有恢复出厂设置。

5、钢板淬火和回火生产线有自保护(过流、过压、水压、相损耗、欠压、过载)系统,在紧急情况下,设备具有自诊断功能。

I-steel plate quenching kanye nomugqa wokukhiqiza wokushisa

Igama lomkhiqizo: steel plate quenching and tempering production line

Izinto zokwakha: insimbi ye-carbon steel alloy, njll.

Ifanele ukujiya: okukhulu kuno-5.0mm

Inqubo: ukushisa, ukucisha

Ukushisa kokushisa: 900-950 ℃

Ibanga lesidingo samandla: 100-8000 kilowatts

Umugqa wokukhiqiza wensimbi wokucisha kanye nokushisa usebenzisa izici zokulawula ukufakwa kwamandla okufudumeza okuphakathi nendawo:

1. I-Parallel resonance design, amandla okushintsha kwesigaba, isici samandla aphezulu, ama-harmonics aphansi, nokusebenza okulula.

2. Ukunikezwa kwamandla kanye ne-inductor kuhlala kugcina ukufanisa okuthembekile nokuphuma kwamandla aphelele. Uma kuqhathaniswa ne-inverter yamandla evamile, ingonga amandla ngo-15-30%.

3. Ukunikezwa kwamandla kungalungisa ngokuzenzakalelayo imingcele yama-workpieces osayizi abahlukene.

4. Ukulawula okugcwele kwesikrini sokuthinta, izilungiselelo ezihlanzekile zedijithali, amarekhodi enqubo ephelele kanye namazinga eziphathimandla aqinile. Setha kabusha njengasekuqaleni.

5. I-steel plate quenching kanye nomugqa wokukhiqiza we-temering unokuzivikela (i-overcurrent, i-overpressure, ingcindezi yamanzi, ukulahlekelwa kwesigaba, i-undervoltage, i-overload) uhlelo. Esimeni esiphuthumayo, okokusebenza kunomsebenzi wokuzixilonga.