- 31

- Dec

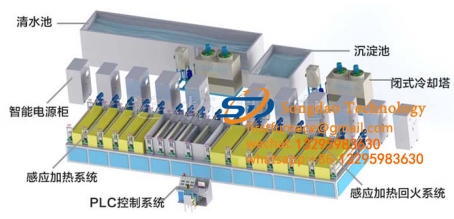

Steel plate quenching and tempering production line

Steel plate quenching and tempering production line

Product name: steel plate quenching and tempering production line

Workpiece material: carbon steel alloy steel, etc.

Suitable for thickness: greater than 5.0mm

Process: heating, quenching

Heating temperature: 900-950℃

Power requirement range: 100-8000 kilowatts

The steel plate quenching and tempering production line adopts intermediate frequency induction heating power supply control features:

1. Parallel resonance design, phase shift power, high power factor, low harmonics, and simple operation.

2. The power supply and the inductor always keep reliable matching with the full power output. Compared with the traditional power inverter, it can save energy by 15-30%.

3. The power supply can automatically adjust the parameters of workpieces of different sizes.

4. Full touch screen control, pure digital settings, complete process records and strict authority levels. Have a factory reset.

5. The steel plate quenching and tempering production line has a self-protection (overcurrent, overpressure, water pressure, phase loss, undervoltage, overload) system. In an emergency, the equipment has a self-diagnosis function.

钢板淬火和回火生产线

产品名称:钢板淬火和回火生产线

工件材料:碳钢合金钢等

适用于厚度:大于5.0mm

过程:加热、淬火

加热温度:900 – 950℃

功率需要范围:100 – 8000千瓦

钢板淬火和回火生产线采用中频感应加热电源控制特点:

1、并联谐振设计,相移功率,功率因数高,谐波小,操作简单。

2、电源和电感器始终保持与全功率输出的可靠匹配,与传统的电源逆变器相比,节能15-30%。

3、该电源可以自动调节不同尺寸工件的参数。

4、全触摸屏控制,纯数字设置,具有完整的流程记录和严格的权限级别。拥有恢复出厂设置。

5、钢板淬火和回火生产线有自保护(过流、过压、水压、相损耗、欠压、过载)系统,在紧急情况下,设备具有自诊断功能。

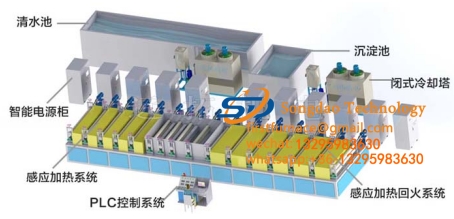

Steel plate quenching and tempering production line

Product name: steel plate quenching and tempering production line

Workpiece material: carbon steel alloy steel, etc.

Suitable for thickness: greater than 5.0mm

Process: heating, quenching

Heating temperature: 900-950℃

Power requirement range: 100-8000 kilowatts

The steel plate quenching and tempering production line adopts intermediate frequency induction heating power supply control features:

1. Parallel resonance design, phase shift power, high power factor, low harmonics, and simple operation.

2. The power supply and the inductor always keep reliable matching with the full power output. Compared with the traditional power inverter, it can save energy by 15-30%.

3. The power supply can automatically adjust the parameters of workpieces of different sizes.

4. Full touch screen control, pure digital settings, complete process records and strict authority levels. Have a factory reset.

5. The steel plate quenching and tempering production line has a self-protection (overcurrent, overpressure, water pressure, phase loss, undervoltage, overload) system. In an emergency, the equipment has a self-diagnosis function.