- 31

- Dec

Steel efere quenching na tempering mmepụta akara

Steel efere quenching na tempering mmepụta akara

Ngwaahịa aha: ígwè efere quenching na tempering mmepụta akara

Ihe eji arụ ọrụ: carbon steel alloy steel, wdg.

Kwesịrị ekwesị maka ọkpụrụkpụ: karịa 5.0mm

Usoro: kpo oku, quenching

Igwe ọkụ ọkụ: 900-950 ℃

Ike chọrọ nso: 100-8000 kilowatts

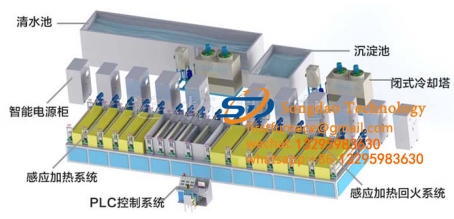

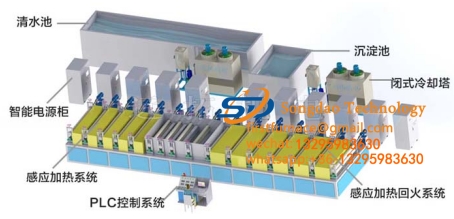

The ígwè efere quenching na tempering mmepụta akara adopts intermediate frequency induction heating power supply control features:

1. Ntugharị resonance imewe, ike mgbanwe nke oge, ike dị elu, ihe nkwekọ dị ala, na ọrụ dị mfe.

2. The ike ọkọnọ na inductor mgbe niile na-a pụrụ ịdabere na kenha na zuru ike mmepụta. E jiri ya tụnyere ihe ntụgharị ike ọdịnala, ọ nwere ike ịchekwa ike site na 15-30%.

3. The ike ọkọnọ nwere ike na-akpaghị aka ịgbanwe parameters nke workpieces nke dị iche iche nha.

4. njikwa ihuenyo mmetụ zuru oke, ntọala dijitalụ dị ọcha, ndekọ usoro zuru oke na ọkwa ikike siri ike. Nwee nrụpụta ụlọ nrụpụta.

5. The ígwè efere quenching na tempering mmepụta akara nwere a onwe-echebe (overcurrent, overpressure, mmiri mgbali, na-adọ ọnwụ, undervoltage, ibufe) usoro. Na mberede, akụrụngwa nwere ọrụ nyocha onwe ya.

钢板淬火和回火生产线

产品名称:钢板淬火和回火生产线

工件材料:碳钢合金钢等

适用于厚度:大于5.0mm

过程:加热、淬火

加热温度:900 – 950℃

功率需要范围:100 – 8000千瓦

钢板淬火和回火生产线采用中频感应加热电源控制特点:

1、并联谐振设计,相移功率,功率因数高,谐波小,操作简单。

2、电源和电感器始终保持与全功率输出的可靠匹配,与传统的电源逆变器相比,节能15-30%。

3、该电源可以自动调节不同尺寸工件的参数。

4、全触摸屏控制,纯数字设置,具有完整的流程记录和严格的权限级别。拥有恢复出厂设置。

5、钢板淬火和回火生产线有自保护(过流、过压、水压、相损耗、欠压、过载)系统,在紧急情况下,设备具有自诊断功能。

Steel efere quenching na tempering mmepụta akara

Ngwaahịa aha: ígwè efere quenching na tempering mmepụta akara

Ihe eji arụ ọrụ: carbon steel alloy steel, wdg.

Kwesịrị ekwesị maka ọkpụrụkpụ: karịa 5.0mm

Usoro: kpo oku, quenching

Igwe ọkụ ọkụ: 900-950 ℃

Ike chọrọ nso: 100-8000 kilowatts

Igwe nchara na-emenyụ ọkụ na ahịrị mmepụta ọkụ na-anabata njirimara njikwa ọkụ ọkụ ọkụ nke etiti oge:

1. Ntugharị resonance imewe, ike mgbanwe nke oge, ike dị elu, ihe nkwekọ dị ala, na ọrụ dị mfe.

2. The ike ọkọnọ na inductor mgbe niile na-a pụrụ ịdabere na kenha na zuru ike mmepụta. E jiri ya tụnyere ihe ntụgharị ike ọdịnala, ọ nwere ike ịchekwa ike site na 15-30%.

3. The ike ọkọnọ nwere ike na-akpaghị aka ịgbanwe parameters nke workpieces nke dị iche iche nha.

4. njikwa ihuenyo mmetụ zuru oke, ntọala dijitalụ dị ọcha, ndekọ usoro zuru oke na ọkwa ikike siri ike. Nwee nrụpụta ụlọ nrụpụta.

5. The ígwè efere quenching na tempering mmepụta akara nwere a onwe-echebe (overcurrent, overpressure, mmiri mgbali, na-adọ ọnwụ, undervoltage, ibufe) usoro. Na mberede, akụrụngwa nwere ọrụ nyocha onwe ya.