- 02

- Nov

Yuav ua li cas xaiv qhov kev sib hloov ceev ntawm qhov chaw tseem ceeb ntawm induction cua sov rauv quenching?

Yuav ua li cas xaiv qhov kev sib hloov ceev ntawm lub ntsiab chaw ntawm induction cua sov cua sov quenching?

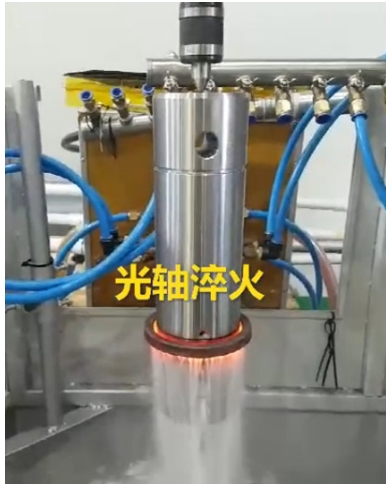

Hais txog kev xaiv ntawm qhov kev sib hloov ceev thaum lub quenched workpiece yog rhuab, nyob rau hauv cov nqe lus ntawm lub uniformity ntawm lub cua sov ntawm lub workpiece, qhov ceev ntawm rotating ceev, qhov me me ntawm qhov kub tsis sib xws vim qhov sib txawv ntawm qhov inductor thiab lub workpiece. . Qhov nrawm ntawm qhov ntxov induction cua sov cua sov quenching feem ntau teem ntawm 60 ~ 300r / min. Qee cov cuab yeej siv tshuab muaj qhov hloov pauv nrawm, thiab qee cov cuab yeej siv tshuab siv qhov hloov pauv tsis hloov, uas tus neeg siv tuaj yeem xaiv arbitrarily. Txawm li cas los xij, qee cov cuab yeej siv tshuab muaj qhov ceev ceev heev vim muaj qee yam mob. Piv txwv li, lub crankshaft phau ntawv journal rotary hardening tshuab, lub ntsiab phau ntawv ceev yog feem ntau 60r / min, thiab txuas qws phau ntawv ceev yog 30r / min. Qhov no yog vim hais tias lub caj dab txuas txuas yog tsim los ntawm lub viav vias mechanism (plaub-txuas rod mechanism) thaum lub sij hawm quenching ntawm induction cua sov rauv Yog hais tias qhov kev sib hloov ceev ceev heev, lub ib nrab-ntiv nplhaib sensor tsis tuaj yeem txav mus los ntawm cov ntawv xov xwm, yog li nws tuaj yeem tig ntawm qhov ceev ntawm 30r / min xwb. Qhov ceev no tsis haum rau cov ntawv xov xwm cua sov. Cov ntawv xov xwm tseem ceeb siv 60r / min yog vim kev siv ob lub cav ceev. Muaj kev sib cav tias qhov kev xaiv ntawm kev ceev yuav tsum tau txiav txim siab raws li lub voj voog cua sov ntawm lub workpiece. Lub workpiece yuav tsum tig tsis pub tsawg tshaj 10 zaug hauv lub voj voog cua sov kom ntseeg tau tias qhov kub thiab txias ntawm qhov ncig ntawm lub workpiece. Raws li qhov kev suav no, lub sijhawm cua sov induction ntawm cov khoom siv dav dav feem ntau yog nruab nrab ntawm 5 thiab 10s, yog tias 5s tig mus rau 1. Yog tias nws tig ntawm 120r / min, yog tias nws tig rau 10s hauv 10s, nws yuav tig ntawm 60r / min.

Nrog rau txoj kev loj hlob ntawm induction cua sov ceev, rau synchronous dual zaus cua sov zog, lub sij hawm cua sov ntawm lub zog tau luv luv rau 0.1 ~ 0.2s. Yog li ntawd, cov kev xav tau ntawm lub workpiece ceev yog nce. Qhov siab tshaj plaws ceev ntawm quenching spindle ntawm ib co induction cua sov cua sovs tau mus txog 1600r / min. Tam sim no, nws tsis tshua muaj qhov quenching ceev ntawm induction cua sov rauv mus txog 600r / min. Tsis tas li ntawd, kev sib hloov ceev ntawm lub workpiece kuj tseem cuam tshuam nrog kev ua kom txias. Rau cov iav thiab spline shafts, quenching txias feem ntau siv txoj kev txau. Kev sib hloov ntawm lub workpiece yog ceev heev, thiab cov kua quenching tsis txaus kom txias ib sab ntawm cov hniav. Yog li ntawd, quenching ceev ntawm lub induction cua sov cua sov tseem yog 600r / min lossis 300r / min raws li qhov txwv siab. Tsis tas li ntawd, nws yog ib qho tsim nyog los tsim cov khoom siv hluav taws xob los yog hluav taws xob uas tuaj yeem txo qhov ceev ntawm lub workpiece nyob rau hauv lub sij hawm tom qab cua sov, yog li ntawd lub workpiece tuaj yeem tig tau sai sai kom ua tiav cov cua sov, thiab nws tuaj yeem tig maj mam kom ua tiav qhov yuav tsum tau ua kom txias txias. iav workpieces.