- 02

- Nov

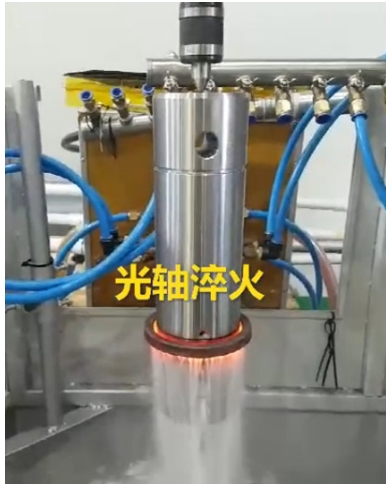

How to choose the rotation speed of the main center of induction heating furnace quenching?

How to choose the rotation speed of the main center of induction heating furnace quenching?

Regarding the selection of the rotating speed when the quenched workpiece is heated, in terms of the uniformity of the heating of the workpiece, the faster the rotating speed, the smaller the influence of temperature unevenness due to the uneven gap between the inductor and the workpiece. The speed range of the early induction heating furnace quenching is generally set at 60~300r/min. Some machine tools have a stepless speed change, and some machine tools use a stepless speed change, which the user can choose arbitrarily. However, some machine tools have extremely low speed due to specific conditions. For example, the crankshaft journal rotary hardening machine, the main journal speed is usually 60r/min, and the connecting rod journal speed is 30r/min. This is because the connecting rod neck is produced by the swing mechanism (four-linked rod mechanism) during the quenching of the induction heating furnace If the rotation speed is too fast, the half-ring sensor cannot stably move across the journal, so it can only rotate at a low speed of 30r/min. This speed is not suitable for journal heating. The main journal uses 60r/min is due to the use of a two-speed motor. There is an argument that the choice of speed should be considered based on the heating cycle of the workpiece. The workpiece should be rotated no less than 10 times in a heating cycle to ensure uniform temperature on the circumference of the workpiece . Based on this calculation, the induction heating time of general workpieces is usually between 5 and 10s, if 5s turns to 1. If it rotates at 120r/min, if it rotates for 10s in 10s, it will rotate at 60r/min.

With the development of induction heating speed, for synchronous dual-frequency heating gears, the heating period of the gears has been shortened to 0.1~0.2s. Therefore, the requirements of the workpiece speed are increasing. The maximum speed of the quenching spindle of some induction heating furnaces has reached 1600r/min. At present, it is rare that the quenching speed of the induction heating furnace reaches 600r/min. In addition, the rotation speed of the workpiece is also closely related to the cooling. For gears and spline shafts, the quenching cooling often adopts the spraying method. The rotation of the workpiece is too fast, and the quenching liquid is insufficient to cool one side of the tooth. Therefore, the quenching speed of the induction heating furnace is still 600r/min or 300r/min as the upper limit. In addition, it is necessary to develop mechanical or electrical components that can reduce the speed of the workpiece in time after heating, so that the workpiece can rotate quickly to achieve uniform heating, and it can rotate slowly to achieve the requirement of uniform cooling of gear workpieces.