- 02

- Nov

Indlela yokukhetha isantya sokujikeleza kwiziko eliphambili lokucima isithando sokufudumala kwe-induction?

Indlela yokukhetha isantya sokujikeleza kweziko eliphambili le ukufakelwa kobushushu bokucima umlilo?

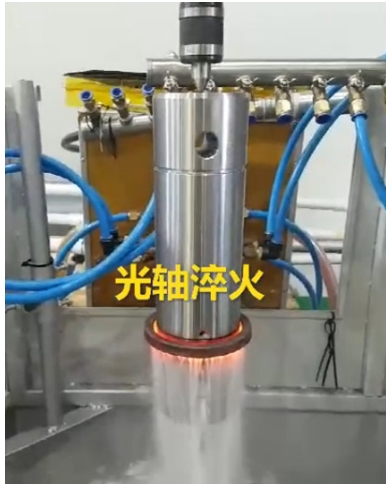

Ngokumalunga nokukhethwa kwesantya esijikelezayo xa i-workpiece ecinyiweyo ishushu, ngokuhambelana nokufana kokufudumeza kwendawo yokusebenza, ngokukhawuleza isantya esijikelezayo, impembelelo encinci yokungalingani kweqondo lokushisa ngenxa yesithuba esingalinganiyo phakathi kwe-inductor kunye ne-workpiece. . Uluhlu lwesantya sokuqala ukufudumeza iziko ukucima ngokuqhelekileyo kubekwe kwi-60 ~ 300r / min. Ezinye izixhobo zoomatshini zinotshintsho lwesantya esingenanyathelo, kwaye ezinye izixhobo zoomatshini zisebenzisa isantya esingena nyathelo, esinokuthi umsebenzisi akhethe ngaphandle kwesizathu. Nangona kunjalo, ezinye izixhobo zoomatshini zinesantya esiphantsi kakhulu ngenxa yeemeko ezithile. Ngokomzekelo, ijenali ye-crankshaft i-rotary hardening machine, isantya esiphezulu sejenali sivame ukuba ngu-60r / min, kunye nesantya sejenali yokudibanisa yi-30r / min. Oku kungenxa yokuba intamo yentonga yokudibanisa iveliswa yindlela yokujingi (intonga edibeneyo ezine) ngexesha lokucinywa kwesithando sokufudumala se-induction Ukuba isantya sokujikeleza sikhawuleza kakhulu, i-sensor-ring-ring ayikwazi ukuhamba ngokuzinzileyo kwijenali. inokujikeleza kuphela ngesantya esiphantsi se-30r / min. Esi santya asifanelanga ukufudumeza ijenali. Ijenali ephambili isebenzisa i-60r / min ngenxa yokusetyenziswa kwe-motor-speed motor. Kukho ingxabano yokuba ukukhethwa kwesantya kufuneka kuthathelwe ingqalelo ngokusekelwe kumjikelezo wokufudumala we-workpiece. I-workpiece kufuneka ijikelezwe ngamaxesha angaphantsi kwama-10 kumjikelezo wokufudumala ukuqinisekisa ukushisa okufanayo kwi-circumference workpiece. Ngokusekelwe kolu balo, ixesha lokufudumala kwe-induction ye-workpieces jikelele lihlala liphakathi kwe-5 kunye ne-10, ukuba i-5 ijika ibe yi-1. Ukuba ijikeleza kwi-120r / min, ukuba ijikeleze i-10 kwi-10s, iya kujikeleza kwi-60r / min.

Ngokuphuhliswa kwesantya sokufudumala kwe-induction, kwi-synchronous dual-frequency heat gears, ixesha lokufudumeza kweegiya liye lancitshiswa ukuya kwi-0.1 ~ 0.2s. Ke ngoko, iimfuno zesantya somsebenzi ziyanda. Esona santya siphezulu sokusonta sokucima kwabanye ukufudumeza izikos ifikelele kwi-1600r / min. Okwangoku, kunqabile ukuba isantya sokucima i-furnace yokufudumeza i-induction ifikelela kwi-600r / min. Ukongeza, isantya sokujikeleza se-workpiece sinxulumene ngokusondeleyo nokupholisa. Kwiigiya kunye ne-spline shafts, ukupholisa ukucima kudla ngokuthatha indlela yokutshiza. Ukujikeleza kwe-workpiece kukhawuleza kakhulu, kwaye ulwelo lokucima alunelanga ukupholisa elinye icala lezinyo. Ke ngoko, isantya sokucima i ukufudumeza iziko kusekho i-600r / min okanye i-300r / min njengomda ophezulu. Ukongeza, kuyimfuneko ukuphuhlisa amacandelo oomatshini okanye ombane anokunciphisa isantya se-workpiece ngexesha emva kokufudumeza, ukwenzela ukuba i-workpiece ikwazi ukujikeleza ngokukhawuleza ukufezekisa ukufudumeza okufanayo, kwaye inokujikeleza ngokukhawuleza ukufezekisa imfuneko yokupholisa okufanayo. izixhobo zokusebenza.