- 14

- Jan

What is the quenching device of the valve end induction heating furnace?

What is the quenching device of the valve end induction heating furnace?

The top of the engine’s intake and exhaust valves are in contact with the valve rocker arm heads, which are easy to wear. For this reason, hardening is required. Generally, the materials of the intake valves and exhaust valves are required to be >40HRCo, and the heating temperature and cooling speed are also different.

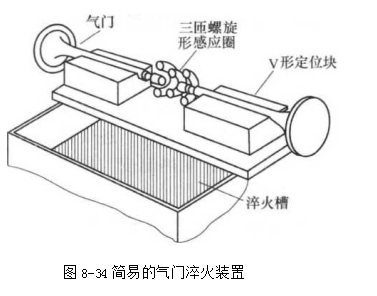

1) A simple valve induction heating furnace quenching device is shown in Figure 8-34. The high-frequency power supply supplies power to a three-turn spiral inductor. The middle turn is slightly smaller than the diameter of the turns at both ends. Place a valve at each end of the center line of the sensor. The valve rod end is located in the center of the sensor. It is only about 8mm. Therefore, after the inductor is energized, the two rod ends are heated to the quenching temperature at the same time. The two V-shaped blocks can locate the center and the axial position. The heating time for the two valves with a 6kW high frequency power supply is 3s. After the valves reach the specified temperature, they are put into the quenching tank below. The quenching cooling medium is generally oil. Due to the large volume of valve production, the automatic valve hardening device has become a very necessary induction heating furnace hardening device.

2) The automatic induction heating furnace quenching device for the valve end is shown in Figure 8-35. Using IGBT super audio frequency transistor power supply, 80kHz, 9kW, the rotary table is controlled by the main drive motor, the radial positioning is also controlled by the motor, and the axial positioning is controlled by the electromagnet. The heating time can be adjusted within 0.1~ 9.95s according to the process needs, and the working cycle is the heating time 0.7s. This machine tool is controlled by a computer and has functions such as parts feeding, heating, exiting, cooling, sending out, etc. It can set process parameters, and has functions such as display, recording, and printing.