- 24

- Dec

Ọdịiche dị n’etiti akụrụngwa ramming kpọrọ nkụ na ihe mgbochi mmiri maka ọkụ etiti oge

The difference between dry ramming material and mmiri ramming ihe maka etiti oge ọkụ

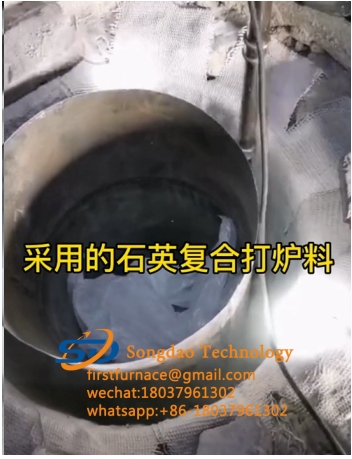

We all know that the material is acidic dry ramming material, which fills the domestic blank. This furnace lining is a pre-mixed dry ramming material. The use of high-quality high-temperature binder has strong crack resistance, high quality and high purity. The quartz sand quartz powder has high temperature resistance, the highest temperature can reach 2000 degrees, and it is widely used in the continuous and intermittent working environment of non-ferrous metals and ferrous metals. This material is used to smelt a series of metal materials such as ordinary steel, 45# steel, high gong steel, high manganese steel, and special steel. The number of heats used can reach more than 120 heats, and the highest can reach 195 heats. The ZH2 type material is used for smelting gray iron, and the number of furnaces used can reach more than 300 furnaces, and the maximum can reach 550 furnaces.

Ramming materials for intermediate frequency furnaces are divided into dry ramming materials and wet ramming materials according to the construction method. The main differences between the two are as follows:

1. N’oge a na-ewu ihe ọkụkụ ramming akọrọ, a na-eji vibration dị elu mee ihe na-eme ka ihe na-asọba na ikpochapu, ka o wee nweta ihe mkpuchi ọkụ ọkụ; A na-agwakọta ihe mgbochi mmiri ahụ na mmiri wee jiri egbe ikuku gbachie ma gwụ ya iji nweta nnukwu mkpuchi ọkụ.

2. Mgbe a rụchara ihe ọkụkụ akọrọ, a na-agbaze taya taya na nchara nchara na usoro oven, a pụkwara ịkwatu ihe mgbochi mmiri na-agbapụta ma jiri ya mee ihe ugboro ugboro.

3. Dry ramming materials are generally suitable for furnaces with relatively large volumes, and wet ramming materials are generally suitable for small intermediate frequency furnaces.