- 19

- Oct

Four main reasons for damage to ladle breathable bricks

Four main reasons for damage to ladle breathable bricks

In the process of using biriky azo zahana rivotra by steel manufacturers, the main reasons for the damage of air-permeable bricks are thermal stress, mechanical stress, mechanical abrasion, and chemical erosion.

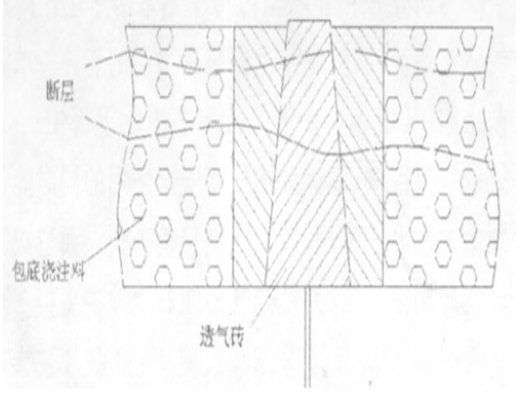

The air-permeable brick consists of two parts: air-permeable core and air-permeable seat brick. When the bottom blowing gas is turned on, the working surface of the air-permeable core will directly contact the high-temperature molten steel. As the number of times of use increases, due to the rapid heat and cold it receives, the deeper the erosion of the core of the ventilating brick will be, and it is easy to produce cracks.

The working surface of the bottom air-permeable brick is in direct contact with the high-temperature molten steel, and the temperature of the non-working surface is relatively low. The volume of the air-permeable brick and nearby refractory materials changes due to temperature changes during the recycling process of steel joining, pouring, and hot repair. The volume change, due to the existence of the temperature gradient and the difference in thermal expansion coefficient between the metamorphic layer and the original layer, the degree of volume change from the working surface of the ventilating brick to the non-working surface gradually changes, which will cause shearing of the ventilating brick. The shear force causes the ventilating brick to have cracks in the transverse direction, and in severe cases, the ventilating brick will break in the transverse direction.

(Picture) Schematic diagram of ventilating brick subjected to mechanical stress

During the tapping process, the molten steel will have a high-strength scouring of the bottom of the ladle, which will accelerate the erosion of the breathable brick. When the upper surface of the breathable brick is higher than the bottom of the bag, it will be sheared and washed by the flow of molten steel. The part higher than the bottom of the bag will generally be washed away after one use. In addition, after refining, if the valve is quickly closed, the reverse impact of molten steel will also accelerate the corrosion of the ventilating brick.

The working surface of the air-permeable brick core is in contact with steel slag and molten steel for a long time. The steel slag and molten steel contain iron oxide, ferrous oxide, manganese oxide, magnesium oxide, silicon oxide, etc., while the components of the air-permeable brick include alumina, silicon oxide, etc. , It will react to generate low-melting substances (such as FeO·Al2O3, 2(MnO)·SiO2·Al2O3, etc.) and be washed away.

(Picture) Low temperature type slit ventilating brick

Specializing in the production of ventilated bricks, burner bricks, electric furnace covers and other refractory materials, with dozens of invention patents and practical patents, professional manufacturers are trustworthy! Focusing on the research and development, production and sales of refractory materials such as ladle breathable bricks for 17 years, it is a professional refractory material manufacturer.