- 27

- Dec

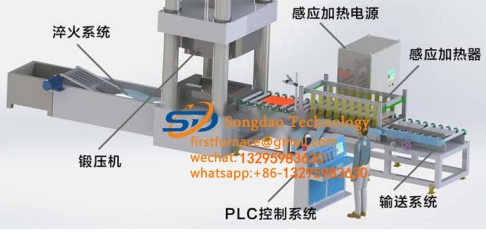

Chitsulo chosapanga dzimbiri mbale otentha anagubuduza kupanga mzere

Chitsulo chosapanga dzimbiri mbale otentha anagubuduza kupanga mzere

Chingwe chopangira chitsulo chosapanga dzimbiri chimapangidwa ndi magetsi apakatikati, cholumikizira chotenthetsera, cholumikizira chodziwikiratu, chida chotulutsa mwachangu, chipangizo choyezera kutentha kwa infrared, ndi cholumikizira chapakati. Pothandizira ma inductors osiyanasiyana, mbale yachitsulo chosapanga dzimbiri imatha kutenthedwa. Kutentha kwa kutentha ndi kusiyana kwa kutentha kwa radial ndi axial kumakwaniritsa zofunikira za ndondomekoyi, ndipo kusungirako kutentha kumatha kuchitika, ndipo kutentha kwa slab iliyonse kukhoza kulembedwa, kutentha ndi yunifolomu, ndi mlingo woyenerera wa mankhwala omalizidwa kwambiri.

Features wa zitsulo zosapanga dzimbiri mbale otentha anagubuduza kupanga mzere:

1. Ikhoza kukwaniritsa mphamvu zambiri, mafupipafupi otsika, kutentha kwabwino, kutentha kwachangu, kuthamanga kwachangu komanso kupanga kwakukulu;

2. Kugwiritsa ntchito voteji ndemanga mndandanda resonance wapakatikati pafupipafupi kupatsidwa ulemu kupatsidwa mphamvu magetsi ulamuliro dera, IGBT pafupipafupi kutembenuka, kutembenuka dzuwa ndi mkulu monga 95% kapena kuposa;

3. Ndi ntchito yowunikira pafupipafupi, mphamvu yayikulu imatha kutsimikiziridwa nthawi zonse, mosasamala kanthu za mphamvu yotulutsa, mphamvu yamagetsi nthawi zonse imakhala yayikulu kuposa 0.9;

4. Poyerekeza ndi thyristor wapakati pafupipafupi ng’anjo, akhoza kupulumutsa mphamvu ndi oposa 30%, ndipo akhoza kuyamba bwinobwino pansi katundu aliyense;

5. Mzere wopangira zitsulo zosapanga dzimbiri zotentha zimakhala ndi zigawo zochepa za harmonic ndipo zimakhala ndi mphamvu zochepa pa gridi yamagetsi;

6. Ili ndi dera lathunthu lachitetezo komanso kudalirika kwakukulu kogwira ntchito;

7. Gawo lamphamvu limatengera kapangidwe kake, komwe ndi koyenera kukonza;

8. Poyerekeza ndi njira zina zachikhalidwe zotenthetsera, kutentha kwa workpiece kumakhala ndi wosanjikiza pang’ono wa oxide, womwe ukhoza kusintha khalidwe la processing la workpiece, kupulumutsa mphamvu ndi zopangira, kuzindikira makina, makina ndi kutuluka, kuchepetsa mphamvu ya ntchito, ndikuwongolera kupanga. chilengedwe.

9. Silab yopyapyala yopangidwa ndi mankhwala imakhala yolimba komanso yopanda mapindikidwe.