- 27

- Dec

Ipleyiti yensimbi engenasici eshushu yokuvelisa umgca wemveliso

Ipleyiti yensimbi engenasici eshushu yokuvelisa umgca wemveliso

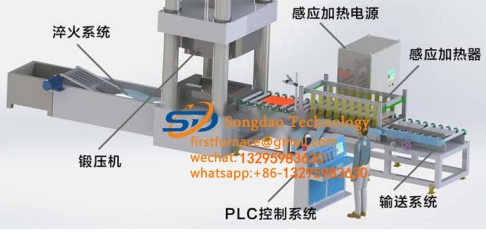

Umgca wemveliso yentsimbi engenastainless idityaniswe ngamandla ombane aphakathi, inzwa yokufudumeza, isixhobo sokutya esizenzekelayo, isixhobo sokukhupha umqulu okhawulezayo, isixhobo sokulinganisa ubushushu be-infrared, kunye neconsole yeziko. Ngokuxhasa ii-inductors ezahlukeneyo, ipleyiti yensimbi engenasici inokufudumeza. Ubushushu bokufudumala kunye nokwahlukana kwe-radial kunye ne-axial yokushisa kuyahlangabezana neemfuno zenkqubo, kwaye ukugcinwa kobushushu kunokufezekiswa, kwaye ubushushu be-slab nganye bunokurekhodwa ngokuzenzekelayo, ukufudumeza kufana, kunye nesantya esifanelekileyo semveliso egqityiweyo ephezulu.

iimpawu steel stainless ipleyiti eshushu rolling linemveliso:

1. Iyakwazi ukufezekisa amandla aphezulu, i-frequency ephantsi, ukushisa kakuhle ukushisa, isantya sokufudumeza ngokukhawuleza kunye nokusebenza kakuhle kwemveliso;

2. Ukusebenzisa i-voltage feedback series resonance intermediate frequency induction yokufudumeza isiphaluka solawulo lonikezelo lwamandla, i-IGBT frequency conversion, ukusebenza kakuhle kokuguqulwa kuphezulu njenge-95% okanye ngaphezulu;

3. Ngomsebenzi wokulandela umkhondo ozenzekelayo, amandla aphezulu ahlala eqinisekisiwe kuyo yonke inkqubo, kungakhathaliseki ukuba yintoni na amandla aphumayo, into yamandla ihlala ikhulu kune-0.9;

4. Xa kuthelekiswa ne-thyristor intermediate frequency furnace, inokugcina amandla ngaphezu kwe-30%, kwaye inokuqala ngempumelelo phantsi kwayo nayiphi na imithwalo;

5. Umgca we-stainless steel stainless hot-rolling production line components eziphantsi kwe-harmonic eziphantsi kwaye zinempembelelo encinci kwigridi yamandla;

6. Inomjikelezo opheleleyo wokukhusela kunye nokuthembeka okuphezulu kokusebenza;

7. Inxalenye yamandla ithatha uyilo lweemodyuli, olulungele ukugcinwa;

8. Xa kuthelekiswa nezinye iindlela zokufudumeza zemveli, ukufudumeza workpiece inomaleko oxide ngaphantsi, nto leyo enokuphucula umgangatho processing of workpiece, ukonga amandla kunye nemathiriyeli ekrwada, ukuqaphela ngokulula oomatshini, automation kunye nemveliso flow, ukunciphisa intensity zabasebenzi, nokuphucula imveliso. okusingqongileyo.

9. I-slab encinci ephathwayo inokuqina okuqinileyo kwaye akukho deformation.