- 26

- Feb

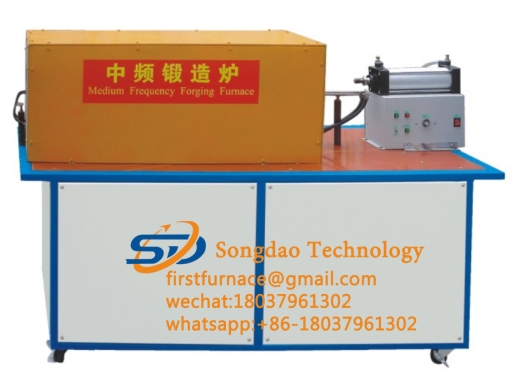

How to choose a forging furnace?

How to choose a forging furnace?

1. Kusankhidwa kwa ng’anjo yopangira ng’anjo ndikoyamba kulabadira kutentha kwa kutentha ndikudziwitsa zakuthupi za workpiece. Kutentha kwa kutentha kwa ntchito yotentha ya zipangizo zosiyanasiyana ndi kosiyana, ndipo kuyenera kukwaniritsa zofunikira za kutentha. Mwachitsanzo, kutentha kutentha kwa aloyi zitsulo zakuthupi ndi madigiri 1200, kutentha kwa aluminiyamu ndi madigiri 450, ndi kutentha kwa zinthu zamkuwa ndi madigiri 1000. Kutentha kwa kutentha kuyenera kutsimikiziridwa malinga ndi zofunikira za ndondomekoyi.

2. Kusankhidwa kwa ng’anjo zopangira kutentha kumayenera kuyang’anitsitsa miyeso yakunja ya workpieces yotentha. Kulemera kwa workpieces mkangano angadziŵike ndi miyeso kunja, kuti adziwe kutentha odzipereka ndi workpieces usavutike mtima kwa ndondomeko kutentha chabe kudziwa Kutentha mphamvu. Kwenikweni, mawonekedwe ndi kukula kwa workpiece kuti atenthetsedwe ndi zazikulu, mipiringidzo yozungulira, ndi zipangizo zolimba, ndi ng’anjo yotentha ya bar yokhala ndi mphamvu yachibale komanso mafupipafupi otsika ayenera kugwiritsidwa ntchito; Mng’anjo yowotcha kwambiri ya bar.

3. Kusankhidwa kwa ng’anjo yopangira ng’anjo kuyenera kulabadira kuya ndi malo a kutentha kwa workpiece. Ngati kutentha kwakuya kuli kozama, malowa ndi aakulu, ndipo kutentha kwakukulu kumachitidwa, ng’anjo yotentha ya bar yokhala ndi mphamvu zambiri komanso yotsika kwambiri iyenera kugwiritsidwa ntchito; Kutentha kwakuya kumakhala kozama, malowa ndi ang’onoang’ono, ndipo kutentha kwapakati kumachitidwa, ndipo ng’anjo yotentha ya bar yokhala ndi mphamvu zochepa komanso maulendo apamwamba ayenera kusankhidwa.

4. Kusankhidwa kwa ng’anjo yopangira ng’anjo kumayenera kumvetsera kutentha kwa workpiece. Kuthamanga kwa kutentha kwa workpiece kuyenera kukhala kofulumira, ndipo ng’anjo yotentha ya bar yokhala ndi mphamvu zazikulu komanso maulendo apamwamba ayenera kusankhidwa.

5. Kusankhidwa kwa ng’anjo yopangira ng’anjo kuyenera kulabadira nthawi yowotchera yosalekeza komanso kuchuluka kwa ma automation, ndikuwonetsetsa ngati ili ndi zida zodziwikiratu komanso zotumizira.

6. Kusankhidwa kwa ng’anjo zowotchera zopangira kuyenera kulabadira mtunda wolumikizana pakati pa zida zoyambira ndi zida. Kulumikizana ndi kwautali, ndipo kumafunikanso kugwiritsa ntchito zingwe zoziziritsa madzi kuti zilumikizidwe. Mng’anjo yapakatikati yotenthetsera yotentha yokhala ndi mphamvu yayikulu iyenera kusankhidwa molingana.

7. Kusankhidwa kwa ng’anjo zowotchera kumayenera kulabadira zofunikira za ndondomekoyi. Nthawi zambiri, panjira monga kuzimitsa ndi kuwotcherera, mphamvu yachibale imatha kusankhidwa kukhala yaying’ono komanso ma frequency kukhala apamwamba. Kuti annealing, kutentha ndi njira zina, mphamvu yachibale iyenera kukhala yokulirapo ndipo ma frequency akhale ochepa. Ena; nkhonya zofiira, calcining yotentha, smelting, etc., ngati ndondomeko yokhala ndi kutentha kwabwino ikufunika, mphamvu iyenera kusankhidwa yokulirapo ndipo mafupipafupi ayenera kusankhidwa pansi.