- 17

- Sep

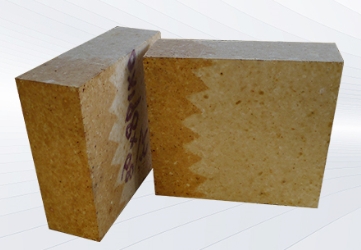

Setene se phahameng sa alumina

Setene se phahameng sa alumina

Melemo ea lihlahisoa: phahameng refractoriness, matla ts’enyeho hanyetsa acid e le alkaline slag, phahameng mocheso matla ho phetha molao feela, matla a phahameng qhoaele hanyetsa, gommage ho hanyetsa, mocheso ho hanyetsa.

Tlhaloso ea Sehlahisoa

Setene se nang le aluminium e phahameng se entsoeng ka setene se nang le aluminium e phahameng se khetholloang ke sebopeho se khabisitsoeng, se entsoeng ka mokato o sebetsang le mocheso oa mocheso. Setene se entsoeng ka likarolo tse ngata ke mohaho o khabisitsoeng o nang le mokato o sebetsang le mocheso oa mocheso, ‘me o na le tšireletso e ntle ea mollo le mocheso. Lera le sebetsang le lera la ho futhumatsa mocheso li arotsoe ka thoko le ho tsoakoa nakong ea litokisetso, ebe li theoa le ho thunngoa hammoho. Lera le sebetsang la setene se kopaneng le na le matla a matla a kopanyang le lera la mocheso. Lera le sebetsang le na le mocheso o phahameng oa ho hanyetsa mocheso, ho hanyetsa acid le alkali, ho hanyetsa abrasion, matla a phahameng, botsitso bo botle ba mocheso, ts’ebetso e ntle ea ho kenya mocheso le matla a mocheso oa mocheso. phahameng. Setene se nang le likarolo tse ngata se ka fihlela litlhoko tsa tekheniki le ts’ebeliso ea sebōpi sa rotary, se ka tseba ho boloka matla le ho fokotsa tšebeliso ea sona, le ho lelefatsa bophelo ba ts’ebeletso ea sebōpi sa rotary. Mokhoa oa ho itokisa ke oa mahlale ebile oa utloahala, o bonolo ebile o bonolo ho o kenya tšebetsong, mme o loketse lebanta la ho thunya le lebanta la sefaele la sebōpi se seholo sa rotary. Ntle le moo, lihlahisoa tsa litene tse nang le likarolo tse ngata tse phahameng li sebelisoa haholo liindastering tse fapaneng joalo ka motlakase, metallurgy, tšepe tse se nang tšepe, petrochemicals, khalase, samente le thepa ea moaho.

Tlhaloso ea litene tse nang le aluminium e phahameng:

1. Likarolo le ts’ebeliso:

E na le ts’ireletso e phahameng, ts’ireletso e matla ea ts’enyeho ho slag le alkaline slag, le matla a phahameng a mochini ka mocheso o phahameng, ka hona e sebelisoa haholo indastering ea tšepe le litsing tse ling. E sebelisoa haholo bakeng sa lera la li-kilns tse futhumatsang tse ngata joalo ka litlhoro tsa setofo sa motlakase, sebopi sa ho phatloha, litofo tse chesang tse chesang, lilanka, meropa ea tšepe, likoloi tsa tšepe, li-kilns tsa samente, li-kilns tsa khalase, jj. E sebelisoa haholo ho etsa tšepe, ho etsa tšepe, lik’hemik’hale , samente le liindasteri tse ling.

2. Litlhaloso tsa lihlahisoa: litene tse tloaelehileng, tse akaretsang le tse ikhethang, tse bopehileng ka mokhoa o ikhethileng le tse ikhethang.

3. Litene tse qhekellang ke thepa e hanang ka sebopeho le boholo bo itseng. Litene tse qhekellang li na le botsitso bo botle ba mocheso ‘me li loketse litofo tse chesang tse chesang, li-linings tse fapaneng tsa boiler, li-flues, likamore tsa mosi, jj. joalo joalo. Litene tse qhekellang hangata li arotsoe ka mefuta e ‘meli, li-Refractories tse sa sebetsoang le tse hahelletsoeng tse bopehileng. Unshaped lintho tse bonahalang refractory: eo hape a bitsoang castable, ke e tsoakiloeng le phofo phofo granule entsoe ka mefuta e fapaneng ya aggregates kapa aggregates le binders ‘ngoe kapa ho feta. Ha e sebelisoa, e kopantsoe le mokelikeli o le mong kapa ho feta ebe e tsoakane ka ho lekana. Ruta motsamao o matla. Lisebelisoa tse bopehileng tse bopehileng: hangata li entsoe ka litene tse sa sebetseng, tse nang le melao e tloaelehileng, hape e ka sebetsoa ka nakoana ho latela litlhoko tsa ha o aha le ho seha.

Litlhahiso tsa ‘mele le lik’hemik’hale

| index ea | Setene se entsoeng ka tikoloho se nang le tikoloho | Tenyetsehang le likarolo tse ngata setene | |||

| HT-1 | HT-2 | HT-3 | HT-4 | HT-5 | |

| Al2O3,% | 0.9 | 1.2 | 1.3 | 1.2 | 1.3 |

| Fe2O3,% | 7.0-9.0 | 7.0-10.0 | – | 3.0-4.0 | 4.0-5.0 |

| SiO2,% ≤ | – | – | 6.0-9.0 | 6.0-9.0 | 4.0-5.0 |

| MgO,% ≥ | 82 | 81 | 83 | 82 | 82 |

| Cr2O3,% | 3.0-4.5 | 3.0-4.5 | 2.0-3.0 | – | – |

| Porosity,% ≤ | 18 | 18 | 18 | 17 | 17 |

| Boholo, g / cm³ ≥ | 3.00 | 2.98 | 2.98 | 2.98 | 2.98 |

| Khatello ea khatello ea mocheso oa kamore, MPa ≥ | 60 | 60 | 70 | 65 | 70 |

| Jarisa mocheso o nolofatsang, ℃ ≥ | 1700 | 1690 | 1690 | 1680 | 1680 |

| Thermal makala 1100 ℃ × metsi tsidifatso ≥ | 11 | 10 | 9 | 9 | 11 |

| Thermal conductivity 1200 ℃ W / m · k ≤ | 2.8 | 2.8 | 2.8 | 2.8 | 2.8 |

| Flexural matla 1400 ℃ × 0.5h MPa ≥ | 4.0 | 4.0 | 4.0 | 3.0 | 3.0 |

dikopo

E loketse lebanta la ho thunya le lebanta la sefene la sebōpi se seholo sa rotary. Ntle le moo, lihlahisoa tsa litene tse nang le likarolo tse ngata tse phahameng li sebelisoa haholo liindastering tse fapaneng joalo ka motlakase, metallurgy, tšepe tse se nang tšepe, petrochemicals, khalase, samente le thepa ea moaho.