- 17

- Sep

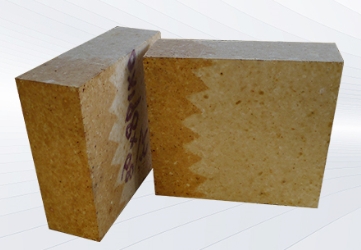

High alumina composite brick

High alumina composite brick

Product advantages: high refractoriness, strong corrosion resistance to acid and alkaline slag, high temperature mechanical strength, high strength wear resistance, peeling resistance, heat shock resistance.

Тавсифи Маҳсулот

High-aluminum composite brick A sintered high-aluminum composite brick is characterized by a layered structure, which is composed of a working layer and a heat insulation layer. The composite brick is a layered structure composed of a working layer and a heat insulation layer, and has a good fire-resistant and heat insulation effect. The working layer and the heat insulation layer are separately batched and mixed during preparation, and then formed and fired together. The working layer of the composite brick has a strong bonding force with the heat insulation layer. The working layer has good high temperature resistance, acid and alkali resistance, abrasion resistance, high strength, good thermal shock stability, good heat insulation performance and strength of the heat insulation layer. high. The composite brick can meet the technical requirements and use requirements of the rotary kiln, can realize energy saving and consumption reduction, and prolong the service life of the rotary kiln. The preparation method is scientific and reasonable, simple and easy to implement, and is suitable for the firing belt and filter belt of a large-scale rotary kiln. In addition, high-alumina composite brick products are widely used in various industries such as electric power, metallurgy, non-ferrous metals, petrochemicals, glass, cement and building materials.

Description of high-aluminum composite bricks:

1. Features and uses:

It has high refractoriness, strong corrosion resistance to acid and alkaline slag, and high mechanical strength at high temperature, so it is widely used in metallurgical industry and other furnaces. It is mainly used for the lining of various thermal kilns such as electric stove tops, blast furnaces, hot blast stoves, ladles, steel drums, iron wagons, cement kilns, glass kilns, etc. It is widely used in ironmaking, steelmaking, chemical, cement and other industries.

2. Product specifications: standard, general and special-shaped, special-shaped and special-shaped bricks.

3. Refractory bricks are refractory materials with a certain shape and size. Refractory bricks have good thermal stability and are suitable for hot blast stoves, various boiler linings, flues, smoke chambers, etc. There are many types of raw materials for refractory bricks, and the main components are soil, stone, sand, ore, powder and so on. Refractory bricks are generally divided into two types, unshaped refractories and shaped refractories. Unshaped refractory material: also called castable, it is a mixed powdery granule composed of a variety of aggregates or aggregates and one or more binders. When used, it is mixed with one or more liquids and mixed evenly. Teach strong mobility. Shaped refractory materials: generally made refractory bricks, the shape of which has standard rules, and it can also be temporarily processed according to needs when building and cutting.

Нишондиҳандаҳои физикӣ ва кимиёвӣ

| шохиси | Environment-friendly composite brick | Flexible composite brick | |||

| HT-1 | HT-2 | HT-3 | HT-4 | HT-5 | |

| Al2O3,% | 0.9 | 1.2 | 1.3 | 1.2 | 1.3 |

| Fe2O3,% | 7.0-9.0 | 7.0-10.0 | – | 3.0-4.0 | 4.0-5.0 |

| SiO2,% ≤ | – | – | 6.0-9.0 | 6.0-9.0 | 4.0-5.0 |

| MgO,% ≥ | 82 | 81 | 83 | 82 | 82 |

| Cr2O3,% | 3.0-4.5 | 3.0-4.5 | 2.0-3.0 | – | – |

| Porosity,% ≤ | 18 | 18 | 18 | 17 | 17 |

| Density, g/cm³ ≥ | 3.00 | 2.98 | 2.98 | 2.98 | 2.98 |

| Pressure resistance at room temperature, MPa ≥ | 60 | 60 | 70 | 65 | 70 |

| Load softening temperature, ℃ ≥ | 1700 | 1690 | 1690 | 1680 | 1680 |

| Thermal shock 1100℃×water cooling ≥ | 11 | 10 | 9 | 9 | 11 |

| Thermal conductivity 1200℃ W/m·k ≤ | 2.8 | 2.8 | 2.8 | 2.8 | 2.8 |

| Flexural strength 1400℃×0.5h MPa ≥ | 4.0 | 4.0 | 4.0 | 3.0 | 3.0 |

Барномаҳо

Suitable for firing belt and filter belt of large rotary kiln. In addition, high-alumina composite brick products are widely used in various industries such as electric power, metallurgy, non-ferrous metals, petrochemicals, glass, cement and building materials.