- 17

- Sep

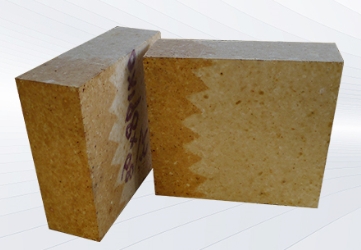

High alumina isitini esiyinhlanganisela

High alumina isitini esiyinhlanganisela

Izinzuzo zomkhiqizo: ukuphindaphinda okuphezulu, ukumelana nokugqwala okuqinile ku-acid ne-alkaline slag, amandla okushisa aphezulu amandla wokuqina, amandla amakhulu wokugqoka ukumelana, ukumelana nokuxebuka, ukumelana nokushisa kokushisa.

incazelo yomkhiqizo

Isitini esiyinhlanganisela esine-aluminium ephezulu Isitini esiyinhlanganisela esine-aluminium ephezulu sihlanganiswa nesakhiwo esigqinsiwe, esakhiwa ungqimba olusebenzayo kanye nongqimba lokushisa okushisa. Isitini esiyinhlanganisela isakhiwo esigqinsiwe esakhiwa ungqimba olusebenzayo kanye nongqimba lokushisa, futhi sinomphumela omuhle wokumelana nomlilo nokushisa. Isendlalelo esisebenzayo nesendlalelo sokushisa sigqokwa ngokuhlukana futhi sixutshwe ngesikhathi sokulungiselela, bese sakhiwa futhi sidutshulwe ndawonye. Isendlalelo esisebenzayo sesitini esiyinhlanganisela sinamandla aqinile okusondeza ungqimba lokuvikela ukushisa. Isendlalelo sokusebenza sinokumelana okuhle kokushisa okuphezulu, ukumelana ne-acid ne-alkali, ukumelana nokuhuzuka, amandla aphezulu, ukuzinza okuhle kokushisa okushisayo, ukusebenza okuhle kokushisa kokushisa namandla wongqimba wokushisa wokushisa. phezulu. Isitini esiyinhlanganisela singahlangabezana nezidingo zobuchwepheshe nezidingo zokusetshenziswa komlilo ojikelezayo, singabona ukonga amandla nokuncishiswa kokusetshenziswa, futhi sandise impilo yensizakalo yomlilo ojikelezayo. Indlela yokulungiselela inesayensi futhi inengqondo, ilula futhi kulula ukuyisebenzisa, futhi ilungele ibhande lokudubula kanye nebhande lokuhlunga lombhobho omkhulu wokujikeleza. Ngaphezu kwalokho, imikhiqizo yezitini eziyinhlanganisela ephezulu isetshenziswa kakhulu ezimbonini ezahlukahlukene njengamandla kagesi, insimbi, izinsimbi ezingezona ezensimbi, ama-petrochemicals, ingilazi, usimende nezinto zokwakha.

Incazelo yezitini eziyinhlanganisela ephezulu:

1. Izici kanye nokusetshenziswa:

It has refractoriness okusezingeni eliphezulu, eqinile ukugqwala ukumelana acid kanye ane-alikhali slag, futhi okusezingeni eliphezulu amandla mechanical at lokushisa eliphezulu, ngakho-ke lisetshenziswa kabanzi embonini metallurgical nakwamanye amaziko. Isetshenziselwa ikakhulukazi ulwelwesi lwama-kilns ahlukahlukene ashisayo njengezigqoko zesitofu sikagesi, iziko lokuqhuma, izitofu zokushisa ezishisayo, amalikhi, imigqomo yensimbi, izinqola zensimbi, izikhuni zikasimende, ama-glass kilns, njll. Isetshenziswa kakhulu ekwenziweni kwensimbi, ekwenzeni insimbi, amakhemikhali , usimende nezinye izimboni.

Ukucaciswa komkhiqizo: izitini ezijwayelekile, ezijwayelekile nezimiswe ngokukhethekile, ezimise okhethekile futhi ezimise okhethekile.

3. Izitini ezi-Refractory yizinto zokuphikisa ezinomumo nosayizi othile. Izitini ezi-Refractory zinokuzinza okuhle kokushisa futhi zilungele izitofu eziqhumayo, amalayili ahlukahlukene wokubilisa, imikhuhlane, amakamelo okubhema, njll. Kunezinhlobo eziningi zezinto zokusetshenziswa zezitini ezikhanyisayo, futhi izingxenye eziyinhloko inhlabathi, itshe, isihlabathi, insimbi, impuphu njalo njalo. Izitini ezinenkani ngokuvamile zehlukaniswa zibe izinhlobo ezimbili, ama-refractories angashintshiwe nama-refractories amile. Okungaxutshiwe kokuphikisayo: okubizwa nangokuthi okungaxubeka, kuyimpuphu ehlanganisiwe eyimpuphu enezinhlanganisela noma okuhlanganisiwe kanye nokuhlanganisa okukodwa noma okungaphezulu. Lapho isetshenziswa, ixutshwa noketshezi olulodwa noma ngaphezulu bese ixubeka ngokulinganayo. Fundisa ukuhamba okunamandla. Izinto zokwakheka ezibunjiwe: okwenziwe ngezitini ezakhayo, okwakheke kunemithetho ejwayelekile, futhi kungacutshungulwa okwesikhashana ngokuya ngezidingo lapho kwakhiwa nokusikwa.

Izinkomba zomzimba nezamakhemikhali

| Inkomba | Isitini esiyinhlanganisela esivumelana nemvelo | Izitini eziyinhlanganisela eziguqukayo | |||

| I-HT-1 | I-HT-2 | I-HT-3 | I-HT-4 | I-HT-5 | |

| I-Al2O3,% | 0.9 | 1.2 | 1.3 | 1.2 | 1.3 |

| I-Fe2O3,% | 7.0-9.0 | 7.0-10.0 | – | 3.0-4.0 | 4.0-5.0 |

| SiO2,% ≤ | – | – | 6.0-9.0 | 6.0-9.0 | 4.0-5.0 |

| MgO,% ≥ | 82 | 81 | 83 | 82 | 82 |

| I-Cr2O3,% | 3.0-4.5 | 3.0-4.5 | 2.0-3.0 | – | – |

| Ukulangazelela,% ≤ | 18 | 18 | 18 | 17 | 17 |

| Ubuningi, g / cm³ ≥ | 3.00 | 2.98 | 2.98 | 2.98 | 2.98 |

| Ingcindezi ukumelana ekamelweni lokushisa, MPa ≥ | 60 | 60 | 70 | 65 | 70 |

| Layisha ukushisa kokuthambisa, ℃ ≥ | 1700 | 1690 | 1690 | 1680 | 1680 |

| Ukushaqeka Thermal 1100 ℃ × amanzi Ukupholisa ≥ | 11 | 10 | 9 | 9 | 11 |

| Ukuqhutshwa kokushisa kwe-1200 ℃ W / m · k ≤ | 2.8 | 2.8 | 2.8 | 2.8 | 2.8 |

| Amandla we-Flexural 1400 ℃ × 0.5h MPa ≥ | 4.0 | 4.0 | 4.0 | 3.0 | 3.0 |

Izicelo

Ifanele ukudubula ibhande nesihlungi sebhande lomlilo omkhulu ojikelezayo. Ngaphezu kwalokho, imikhiqizo yezitini eziyinhlanganisela ephezulu isetshenziswa kakhulu ezimbonini ezahlukahlukene njengamandla kagesi, insimbi, izinsimbi ezingezona ezensimbi, uphethiloli, ingilazi, usimende nezinto zokwakha.