- 16

- Nov

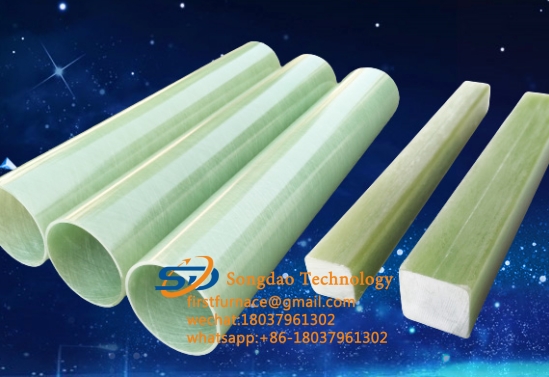

Do you know several characteristics of epoxy glass fiber pipe?

Do you know several characteristics of epoxy glass fiber pipe?

The epoxy glass fiber tube is made of electrician alkali-free glass fiber cloth impregnated with epoxy resin, baked, and processed by hot pressing in a forming mold. The cross section is a round rod. The glass cloth rod has high mechanical properties. The surface of the epoxy glass fiber tube should be smooth without any bubbles, oil stains and impurities. Uneven color, slight rubbing, etc. are all within the allowable range. Epoxy fiberglass pipes are used for parts of insulation structure in electrical equipment, humid environment conditions and transformer oil.

The characteristics of epoxy glass fiber pipes are relatively wide, and the scope of application is relatively wide, and the forms are diverse. The resin, curing agent, and modifier system can almost adapt to the requirements of various applications on the form, and the range can be from extremely low viscosity to high melting point solids. Secondly, the curing is very convenient. Choose a variety of different curing agents, and the epoxy resin system can be cured at a temperature range of 0-180°C.

One thing I have to mention is that it has strong adhesion. There are polar hydroxyl groups and ether bonds in the molecular chain of epoxy resin, which makes it have high adhesion to various substances. The shrinkage of epoxy resin is low when curing, and the internal stress generated is small, which also helps to improve the adhesion strength. It also has low shrinkage. The reaction between epoxy resin and curing agent is carried out by direct addition reaction or ring-opening polymerization reaction of epoxy groups in the resin molecule, and no water or other volatile by-products are released. According to relevant data, compared with unsaturated polyester resin and phenolic resin, the shrinkage during the curing process is very low, about 2%. .