- 03

- Nov

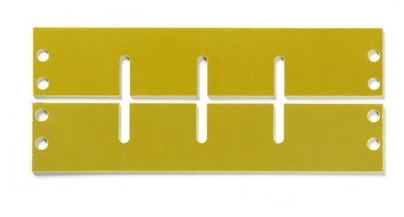

Introduction to the application functional characteristics of epoxy glass fiber board

Introduction to the application functional characteristics of epoxy glass fiber board

Epoxy glass fiber board, epoxy phenolic laminated glass cloth board, epoxy resin generally refers to organic polymer compounds containing two or more epoxy groups in the molecule, except for some, their relative molecular masses are not high. The molecular structure of epoxy resin is characterized by the active epoxy group in the molecular chain. The epoxy group can be located at the end, in the middle or in a cyclic structure of the molecular chain. Because the molecular structure contains active epoxy groups, they can undergo cross-linking reactions with various types of curing agents to form insoluble and infusible polymers with a three-way network structure.

Epoxy glass fiber board application characteristics and functions:

1. Cov khoom siv dag zog. Cov txheej txheem kho epoxy resin muaj cov cuab yeej zoo heev.

2. Muaj zog nplaum. Cov pab pawg hydroxyl ncov qaumteb qabteb thiab cov ether bonds hauv cov saw hlau molecular ntawm epoxy resins ua rau nws nplaum rau ntau yam tshuaj. Kev nqaim ntawm epoxy resin yog qis thaum kho, thiab kev nyuab siab sab hauv tsim tawm me me, uas tseem pab txhim kho lub zog ua kom khov.

3. Yooj yim kho. Xaiv ntau yam sib txawv ntawm cov neeg sawv cev kho kab mob, cov txheej txheem epoxy tuaj yeem yuav luag tau kho hauv qhov kub ntawm 0 ~ 180 ℃.

4. Ntau hom ntawv. Ntau yam resins, kho tus neeg sawv cev, thiab hloov kho cov txheej txheem tuaj yeem hloov kho kom tau raws li qhov xav tau ntawm ntau daim ntawv thov ntawm daim ntawv, thiab qhov ntau tuaj yeem yog los ntawm qis viscosity mus rau qhov siab melting point khib nyiab.

5. Tsawg shrinkage. Cov tshuaj tiv thaiv ntawm cov tshuaj epoxy cob thiab cov tshuaj tua kab siv yog ua los ntawm cov tshuaj tiv thaiv ncaj qha ntxiv lossis lub nplhaib-qhib polymerization cov tshuaj tiv thaiv ntawm epoxy pawg hauv cov tshuaj molecule, thiab tsis muaj dej lossis lwm yam khoom hloov pauv tau tso tawm. Piv nrog cov polyester tsis txaus satin thiab cov phenolic resins, lawv qhia qis qis qis (tsawg dua 2%) thaum kho.