- 03

- Nov

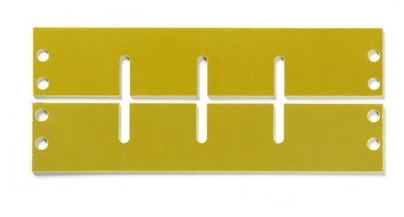

Isingeniso sohlelo lokusebenza nezici ze-epoxy glass fiber board

Isingeniso somsebenzi wohlelo lokusebenza izici ze-epoxy glass fiber board

Ibhodi le-epoxy glass fibre board, ibhodi lendwangu yengilazi ye-epoxy phenolic laminated, i-epoxy resin ngokuvamile ibhekisela kumakhompiyutha e-polymer ephilayo aqukethe amaqembu e-epoxy amabili noma ngaphezulu ku-molecule, ngaphandle kwamanye, izixuku zawo zamangqamuzana aziphezulu. Isakhiwo samangqamuzana e-epoxy resin sibonakala ngeqembu le-epoxy elisebenzayo kuketango lamangqamuzana. Iqembu le-epoxy lingatholakala ekugcineni, phakathi nendawo noma esakhiweni se-cyclic seketango lamangqamuzana. Ngenxa yokuthi ukwakheka kwamangqamuzana kuqukethe amaqembu e-epoxy asebenzayo, angabhekana nokusabela okuxhumanisa ngezinhlobo ezahlukene zama-ejenti okwelapha ukuze akhe ama-polymer angancibilikiyo futhi angenakunyakaziswa anesakhiwo senethiwekhi yezindlela ezintathu.

Izici nemisebenzi ye-epoxy glass fiber board:

1. Izakhiwo zemishini. I-epoxy resin system ephulukisiwe inezakhiwo ezinhle kakhulu zomshini.

2. Ukunamathela okuqinile. Amaqembu aphethwe yi-polar hydroxyl kanye nezibopho ze-ether ochungechungeni lwamangqamuzana ezinhlaka ze-epoxy zikwenza kube ukunamathela kakhulu ezintweni ezahlukahlukene. Ukuncipha kwe-epoxy resin kuphansi lapho welapha, futhi ukucindezela kwangaphakathi okukhiqizwe kuncane, okusiza nokwenza ngcono amandla wokubambelela.

3. Ukwelapha okulula. Khetha ama-ejenti ahlukahlukene aphulukisayo, uhlelo lwe-epoxy resin cishe lungalapheka ebangeni lokushisa elingu-0 ~ 180 ℃.

4. Amafomu ahlukahlukene. Izinhlaka ezahlukahlukene, ama-ejenti aphulukisayo, kanye nezinhlelo zokuguqula cishe zingazivumelanisa nezidingo zezinhlelo zokusebenza ezahlukahlukene kwifomu, futhi ububanzi bungaba kusuka ku-viscosity ephansi kakhulu kuye kokuqina okuphezulu kokuncibilika.

5. Ukuncipha okuphansi. Ukusabela phakathi kwe-epoxy resin kanye ne-ejenti ephulukisayo esetshenziswayo kwenziwa ngokufaka okuqondile ngqo noma ukuvulwa kwendandatho kokuphendula kwamaqembu epoxy ku-molecule ye-resin, futhi awekho amanzi noma eminye imikhiqizo evela ezintekenteke ekhishwayo. Uma kuqhathaniswa nezinhlayiya ze-polyester ezingasetshenziswanga nama-phenolic resins, akhombisa ukuncipha okuphansi kakhulu (ngaphansi kuka-2%) ngesikhathi sokuphulukiswa.