- 07

- Oct

Working environment of argon blowing and breathable bricks at the bottom of ladle

Working environment of argon blowing and lélegző téglák at the bottom of ladle

In the process of refining molten steel in the ladle, it is very important for steel manufacturers to complete the production by means of the bottom blowing argon process of the ventilating brick. The function of the bottom argon blowing ventilating brick is to stir the molten steel by blowing argon at the bottom to make the molten steel circulate. The purpose of adjusting the composition of molten steel and removing inclusions.

In the process of refining molten steel in the ladle, it is very important for steel manufacturers to complete the production by means of the bottom blowing argon process of the ventilating brick. The function of the bottom argon blowing ventilating brick is to stir the molten steel by blowing argon at the bottom to make the molten steel circulate. The purpose of adjusting the composition of molten steel and removing inclusions. Therefore, the air permeability of the ladle air-permeable bricks has a great impact on the refining outside the furnace. If the air is not air-tight or the air permeability is small, the molten steel refining work cannot be completed. In addition, if the air permeability is too large, it will affect the lining of the ladle with other refractory materials. Service life.

(Picture) Baking ladle

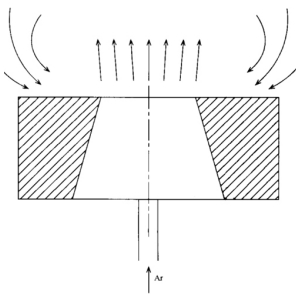

During the production process, the ladle bottom blown and breathable bricks have to withstand: air flow (argon) and molten steel erosion, molten slag erosion after the continuous casting of molten steel, and melting loss and turnover caused by the oxygen pipe blowing and cleaning the working surface of the breathable brick during hot repair Extremely cold and hot in the process and damage caused by mechanical vibration during lifting.

In the process of refining, the ladle breathable brick needs to blow argon at the bottom of the whole process. The air flow is blown into the ladle with higher pressure, and the molten steel is stirred continuously. On the surface, it is the tumbling and boiling of the molten steel. At the same time, due to the reaction force of the airflow, the air-permeable brick and the surrounding refractory materials will be subject to a large degree of erosion.

After the molten steel is completed on the continuous casting, until the steel slag is completely poured out, the working surface of the ventilating brick will come into contact with the slag, and part of the oxides in the slag will react with the brick to form a eutectic to make the ventilating brick Eroded by erosion.

(Picture) The working principle of breathable brick

When cleaning the working surface of breathable bricks, the method of low argon blowing and oxygen lance blowing is generally used. Connect the joint of the argon gas pipe to the tail pipe of the breathable brick, open the valve, and the high-pressure gas will flow into the breathable brick. At the same time, the hot repair worker uses an oxygen lance to blow the residual steel slag on the surface of the breathable brick until the working surface of the breathable brick changes slightly. Until dark.

The steel ladle is connected intermittently, and the rapid cold and hot before and after the steel is connected, and the steel ladle is inevitably subjected to collision during the hoisting process, resulting in mechanical damage.

It can be seen that the quality of bottom-blown argon breathable bricks is very important to steel manufacturers. The higher the quality of the breathable bricks, the higher the output and quality of the corresponding steel. Firstfurnace@gmil.com, as a professional manufacturer of ventilated bricks, has been developing, producing and selling ventilating bricks for 18 years. The products are of high quality, with long life, thermal shock resistance, erosion resistance, erosion resistance and other excellent characteristics!