- 28

- Sep

Correct use of CNC quenching machine tools

Ojiji nke ọma CNC quenching igwe ngwaọrụ

During processing, the workpiece can rotate in both directions, and the speed of the parts can be smoothly adjusted through the adjustment of the frequency converter. The use of a double-group top structure makes the processing productivity of the parts significantly improved. In order to suit the processing of workpieces of different lengths, the height of the upper center is adjusted electrically. Through the automatic control of different output channels of the power supply provided by the control system, the variable power control function in the processing process can be realized. Through keyboard programming, the user can call the corresponding quenching program at any time, so as to realize the automatic control of continuous quenching, subsection continuous quenching, subsection simultaneous quenching and simultaneous quenching. It is also equipped with a quenching liquid circulating cooling system and an auxiliary liquid spraying system integrated with the machine tool.

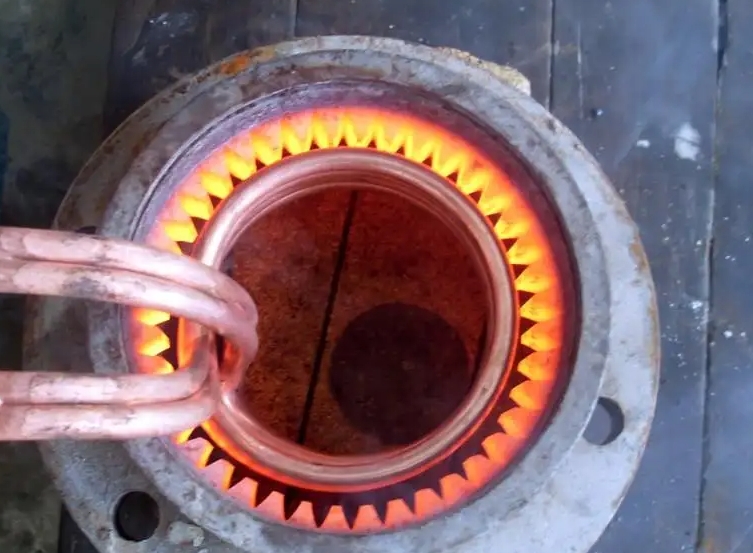

Because the induction heating uses a medium and high frequency power supply, the processing environment has the characteristics of high voltage, high current and strong magnetic field. In addition, the water vapor, fog and burrs appear in the cold working process of the whole quenching process, so the induction quenching scene is very complicated, and it is automatic. Control brings complex requirements, which is the correct use of CNC quenching machine tools.