- 28

- Sep

Riktig bruk av CNC bråkjølingsmaskiner

Riktig bruk av CNC bråkjølingsmaskiner

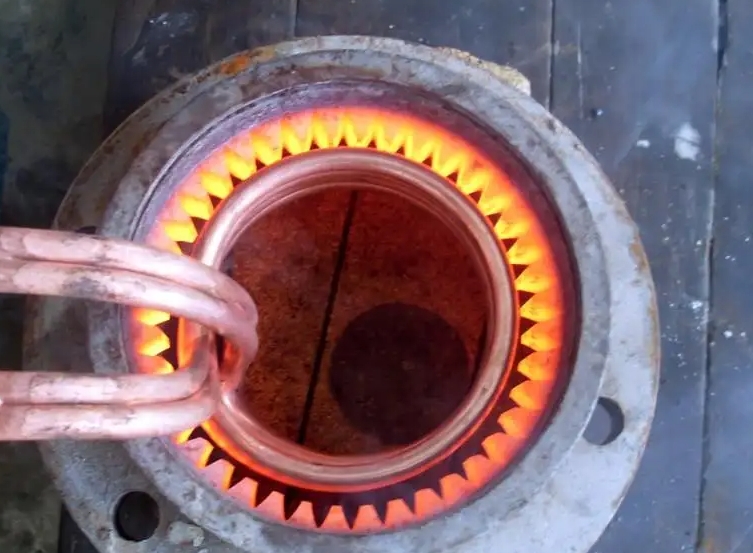

During processing, the workpiece can rotate in both directions, and the speed of the parts can be smoothly adjusted through the adjustment of the frequency converter. The use of a double-group top structure makes the processing productivity of the parts significantly improved. In order to suit the processing of workpieces of different lengths, the height of the upper center is adjusted electrically. Through the automatic control of different output channels of the power supply provided by the control system, the variable power control function in the processing process can be realized. Through keyboard programming, the user can call the corresponding quenching program at any time, so as to realize the automatic control of continuous quenching, subsection continuous quenching, subsection simultaneous quenching and simultaneous quenching. It is also equipped with a quenching liquid circulating cooling system and an auxiliary liquid spraying system integrated with the machine tool.

Fordi induksjonsoppvarmingen bruker en middels og høyfrekvent strømforsyning, har prosessmiljøet egenskapene til høyspenning, høy strøm og sterkt magnetfelt. I tillegg vises vanndamp, tåke og grader i den kalde arbeidsprosessen under hele bråkjølingsprosessen, så induksjonsslukningsscenen er veldig komplisert, og den er automatisk. Kontroll bringer komplekse krav, som er riktig bruk av CNC bråkjølingsmaskiner.