- 28

- Sep

Ukusetshenziswa okulungile kwamathuluzi omshini wokucisha we-CNC

Ukusetshenziswa okulungile kwe Amathuluzi omshini wokucisha we-CNC

Ngesikhathi sokucubungula, i-workpiece ingajikeleza kuzo zombili izinkomba, futhi isivinini sezingxenye singalungiswa kahle ngokulungiswa kwesiguquli semvamisa. Ukusetshenziswa kwesakhiwo esiphezulu seqembu eliphindwe kabili kwenza ukukhiqizwa kokucubungula kwezingxenye kube ngcono kakhulu. Ukuze kuhambisane nokucutshungulwa kwama-workpieces obude obuhlukene, ukuphakama kwesikhungo esiphezulu kulungiswa ngogesi. Ngokulawula okuzenzakalelayo kwamashaneli okukhiphayo ahlukene okunikezwa kwamandla okuhlinzekwa yisistimu yokulawula, umsebenzi wokulawula amandla oguquguqukayo enqubweni yokucubungula ungenziwa. Ngokusebenzisa uhlelo lwekhibhodi, umsebenzisi angashayela uhlelo lokucisha oluhambisanayo nganoma yisiphi isikhathi, ukuze abone ukulawula okuzenzakalelayo kokucisha okuqhubekayo, ukucisha isigatshana okuqhubekayo, ukucisha isigatshana kanyekanye kanye nokucisha kanyekanye. Iphinde ifakwe i-quenching liquid circulating system kanye nesistimu yokufafaza uketshezi olusizayo oluhlanganiswe nethuluzi lomshini.

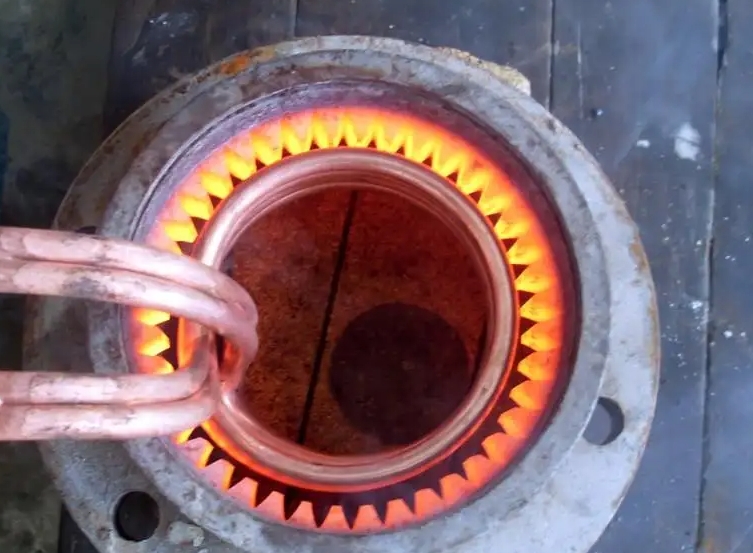

Ngenxa yokuthi ukushisisa kwe-induction kusebenzisa amandla aphakathi nendawo naphezulu, indawo yokucubungula inezici zamandla kagesi aphezulu, inkambu yamanje ephezulu kanye namandla kazibuthe. Ukwengeza, umhwamuko wamanzi, inkungu nama-burrs avela enkambweni ebandayo yokusebenza kwayo yonke inqubo yokucisha, ngakho-ke indawo yokucisha i-induction iyinkimbinkimbi kakhulu, futhi iyazenzakalela. Ukulawula kuletha izidingo eziyinkimbinkimbi, okuwukusetshenziswa okufanele kwamathuluzi omshini wokucisha i-CNC.