- 28

- Sep

Cepet ngganti Chuck kanggo quenching induktor

Cepet ngganti Chuck kanggo quenching induktor

Sambungan antarane inductor and the quenching transformer requires strong electrical connection, low resistance, and reliability. The early design of the inductor and the transformer contact plate are connected with bolts and nut washers: the intermediate frequency sensor has two rows of M12 bolts, a total of 10 bolts; the high frequency sensor also has M8 or M10 bolts, a total of 4 bolts. It is time-consuming and laborious to load and unload the sensor once, and the cooling water inlet and outlet pipes need to be connected to the sensor, which increases the auxiliary time.

Cepet-owahan Chuck kanggo sensor

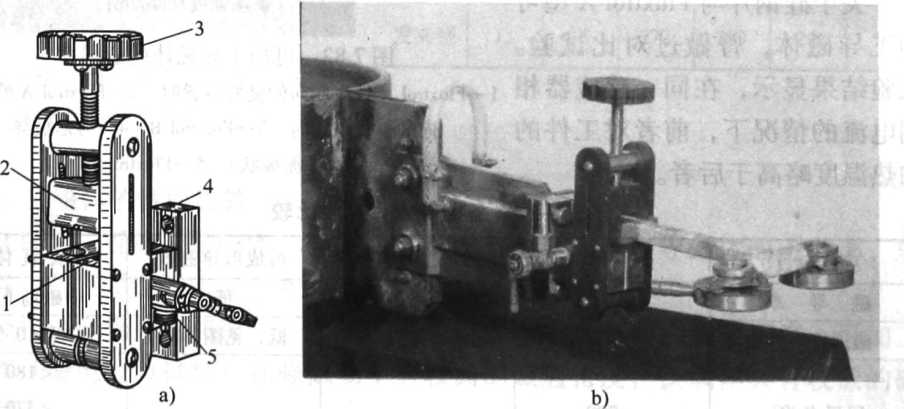

Gambar nuduhake chuck cepet-owahan kanggo sensor, kang dumadi saka awak plate kontak, nangani mencet, pemblokiran mencet, ring sealing lan tutup welingan banyu. Ing tengah ngarep ana port selipan saka sensor, lan loro dering sealing punika welingan banyu lan stopkontak sensor. Nalika sensor karo struktur standar pemblokiran sambungan lumebu ing port selipan, corak nangani 3, bakelite penet pemblokiran mekso pemblokiran sambungan kanggo lumahing ngisor port selipan, lan sambungan banyu lan listrik rampung ing siji wektu. Nalika ngganti sensor, katup inlet banyu 5 bisa ditutup. Kanthi struktur iki, butuh udakara 10 detik kanggo ngganti sensor, sing nambah efisiensi kerja lan ngirit tenaga kerja. Chuck iki wis akeh digunakake ing produksi lan luwih cocok kanggo daya frekuensi dhuwur ngisor 60kW.

Gambar Sensor chuck pangowahan cepet lan sensor

a) Cepet-ganti Chuck b) Cepet-owahan Chuck karo sensor

1 cincin penyegel 2 blok tekanan 3 gagang 4 badan pelat kontak 5 katup inlet banyu